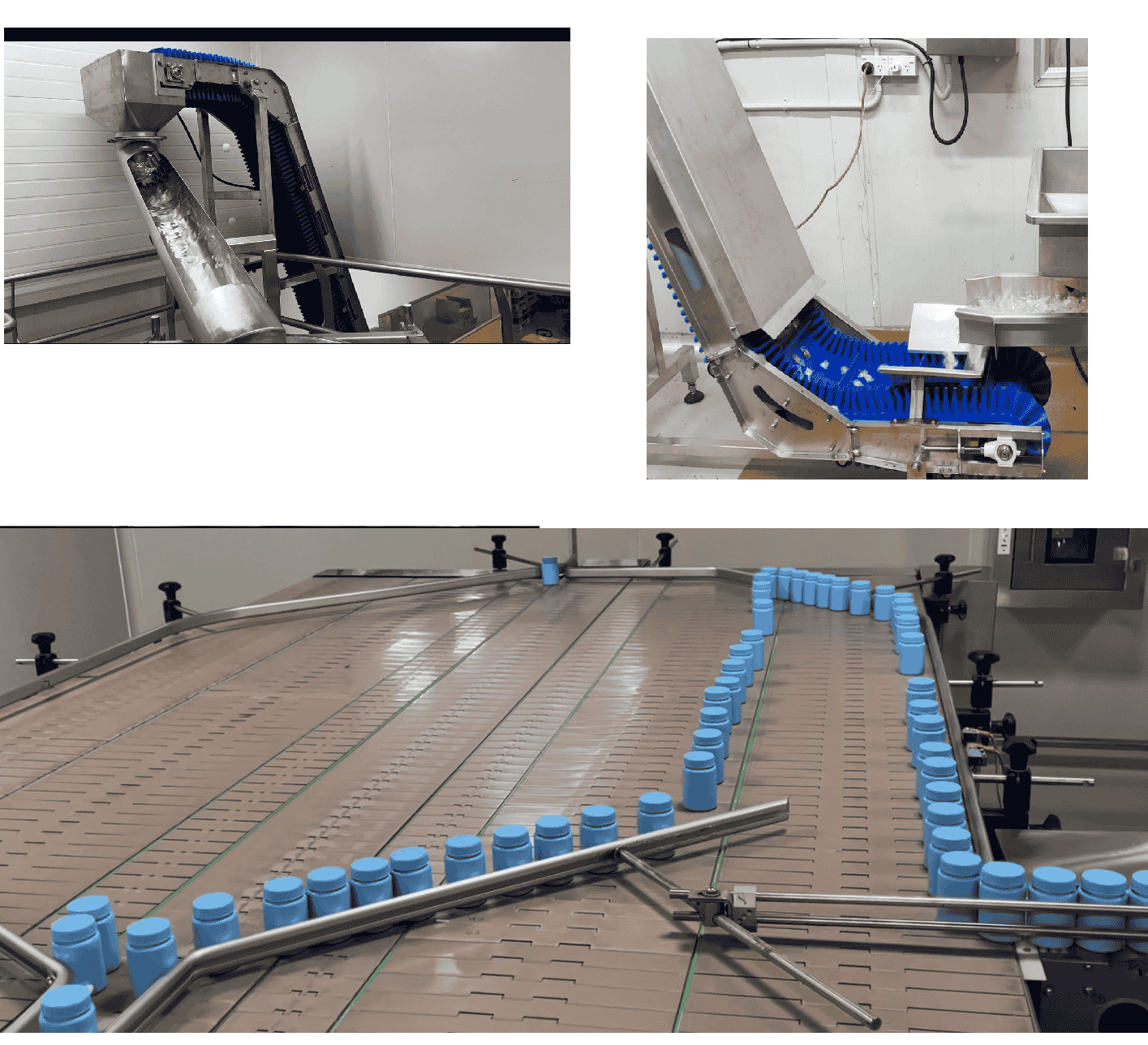

Conveyor Systems

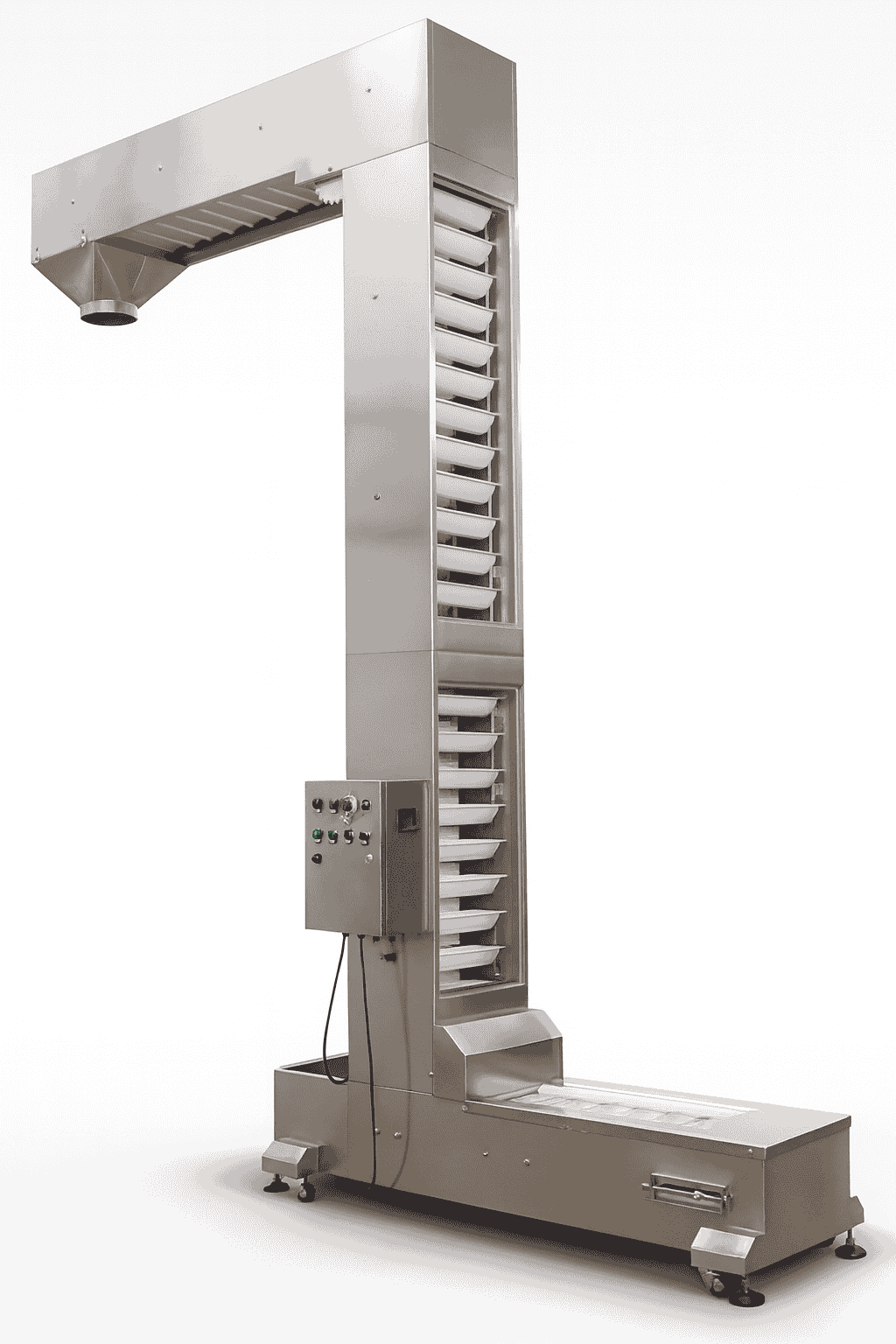

The Conveyor Systems by MEF are designed to deliver uninterrupted product flow across every stage of the packaging line. Engineered to handle cartons, bottles, pouches, bags, trays, and shrink packs, our conveyors ensure smooth, reliable transfers between processing, filling, cartoning, case packing, palletizing, and de-palletizing stations. With stainless-steel construction, energy-efficient drives, and modular layouts, MEF conveyors are built for durability, hygiene, and easy maintenance. From straight runs and 90° transfers to incline, decline, accumulation, and multi-lane systems, each conveyor is custom-designed to fit your production flow. Trusted in food, pharmaceutical, cosmetic, and FMCG industries, MEF’s conveyor solutions increase line efficiency, reduce downtime, and provide future-ready automation for modern manufacturing environments.Why Choose MEF Conveyor Systems?

Continuous Product Flow

The MEF conveyor range is engineered to maintain uninterrupted movement of cartons, bottles, pouches, and trays, ensuring smooth transitions between filling, cartoning, packing, and palletizing stations.

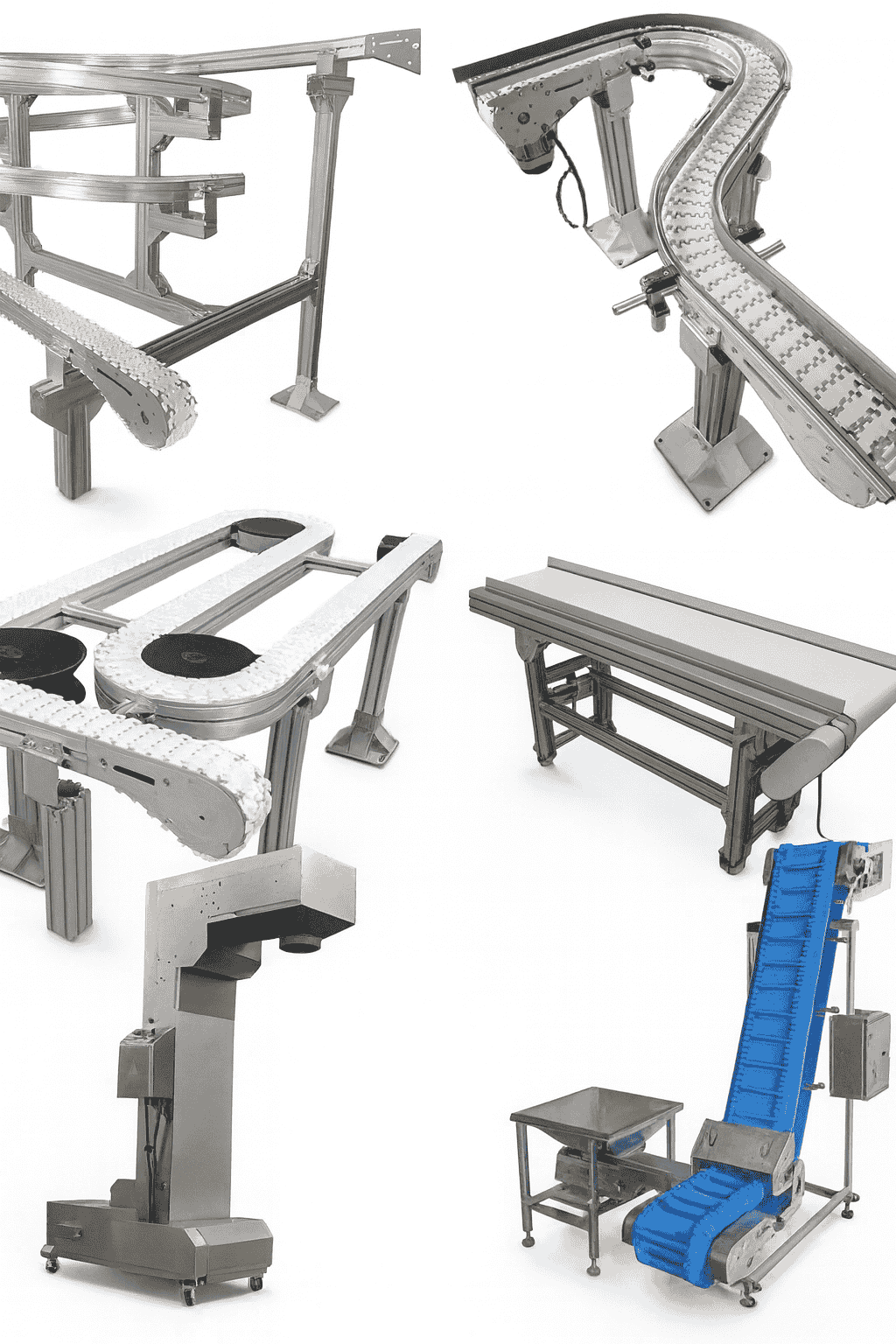

Versatile Configurations

Available in modular belt, roller, slat chain, and incline/decline designs, MEF conveyors adapt to diverse layouts and product requirements, from simple transfers to complex multi-lane systems.

Hygienic & Durable Design

Built with SS304/SS316 stainless steel construction, our conveyors meet GMP standards for food and pharmaceutical lines while offering long-term durability in high-volume operations.

Energy-Efficient Operation

Equipped with servo or VFD-driven motors, MEF conveyors optimize energy usage while maintaining consistent speed, alignment, and throughput.

Flexible Integration

Designed to work seamlessly with cartoners, case packers, palletizers, and de-palletizers, delivering a connected packaging ecosystem.

Low Maintenance & Easy Access

Featuring modular belts, quick-release guides, and open-frame construction, MEF conveyors reduce downtime and simplify cleaning and maintenance tasks.

Scalable & Customizable

Whether for short runs, long distances, accumulation zones, or elevation changes, MEF offers conveyor solutions tailored to each facility’s requirements.

Trusted by pharma, food, cosmetics, and FMCG industries, MEF conveyor systems provide efficient product flow, minimal downtime, and future-ready automation for end-to-end packaging lines.

Technical Specifications

| Material of Construction (MOC) | Stainless steel SS304 frame with food-grade belts; SS316 options available for high-hygiene pharma & food applications. |

|---|---|

| Conveyor Types | Modular belt, slat chain, roller, timing belt, and incline/decline conveyors. |

| Operating Speed | Variable from 10 to 60 meters/minute (servo or VFD controlled, depending on product flow and line configuration). |

| Drive & Control | Equipped with ABB/Siemens/Allen-Bradley motors & drives; PLC integration with recipe-based speed and stop/start control. |

| Power Requirement | Approx. 1.5–3.0 kW depending on conveyor type, length, and load capacity; 415 V, 3-phase, 50 Hz. |

| Belt Width & Length | Customizable from 150 mm to 1200 mm width and up to 20 meters length; designed per layout requirements. |

| Load Capacity | Handles up to 100 kg/meter depending on conveyor type (roller/slat for heavy loads, modular belt for cartons & packs). |

| Changeover | Tool-less belt and guide adjustments; modular sections allow quick replacement and line reconfiguration. |

| Machine Weight | Varies by configuration: typically 200–800 kg per conveyor section. |

| Design Features | Open-frame construction for cleanability, side guides for product alignment, accumulation zones, and optional curved or Z-shaped layouts. |

Optional Features

- Custom belt materials (PU, PVC, modular plastic, stainless steel wire mesh) for different product types

- Incline/decline modules with cleated belts for elevation changes

- Curved and 90° transfer sections for complex layouts

- Accumulation zones for buffering and controlled product flow

- Side guides, sensors, and reject systems for product alignment & quality control

- Washdown-ready designs for food & pharmaceutical hygiene standards

- Energy-efficient drives and low-maintenance modular components

Integration with Packaging Lines

The MEF Conveyor Systems are built for seamless transfer of products between cartoners, case packers, palletizers, and de-palletizers. Designed for high-speed packaging lines, they ensure smooth product movement from filling to end-of-line automation.

Explore: Palletizers · De-Palletizers

Watch our conveyors in action

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of MEF Conveyor Systems

- Continuous product transfer: Ensures smooth, vibration-free movement of cartons, bottles, pouches, and trays across the line.

- Multiple conveyor designs: Available in modular belt, roller, slat chain, and incline/decline options for diverse packaging needs.

- Customizable layouts: Straight runs, curves, accumulation zones, and multi-lane systems tailored to your factory layout.

- Hygienic construction: Built with SS304/SS316 stainless steel for food and pharma applications with easy wash-down access.

- Smart drive control: Servo or VFD-driven motors with adjustable speed, stop/start synchronization, and energy efficiency.

- Seamless connectivity: Integrates with cartoners, case packers, palletizers, and de-palletizers to create a unified packaging flow.

Looking to optimize your line? MEF conveyors are designed for scalability, flexibility, and long-term reliability.

- Reduced downtime: Tool-less adjustments and modular sections make maintenance quick and simple.

- Improved efficiency: Consistent product spacing and flow balance prevent bottlenecks.

- Adaptability: Suitable for both high-speed lines and manual operations.

- Future-ready: Compatible with Industry 4.0 monitoring, remote diagnostics, and smart factory systems.

Applications

Designed for reliable product transport in industries requiring high-speed, hygienic, and flexible packaging operations.

- Pharma blisters, bottles, vials, and cartons

- Food & beverage pouches, jars, snack bags, and shrink packs

- Cosmetic tubes, kits, and retail-ready multipacks

- FMCG and consumer goods cartons, trays, and e-commerce packs

Key Details

- Operating speeds up to 60 m/min with servo/VFD control

- Belt width customizable from 150 mm to 1200 mm

- Load capacity up to 100 kg per meter

- Energy-efficient design requiring ~1.5–3.0 kW depending on type

Industries & Applications

- Pharmaceutical & nutraceutical: Bottle transport, blister handling, secondary carton flow

- Food & beverages: Chocolate bars, snack pouches, beverage bottles, bakery trays

- Cosmetics & personal care: Tubes, creams, display packs, multipacks

- FMCG & consumer goods: Household products, electronics, accessories