Multihead Weigher Machine

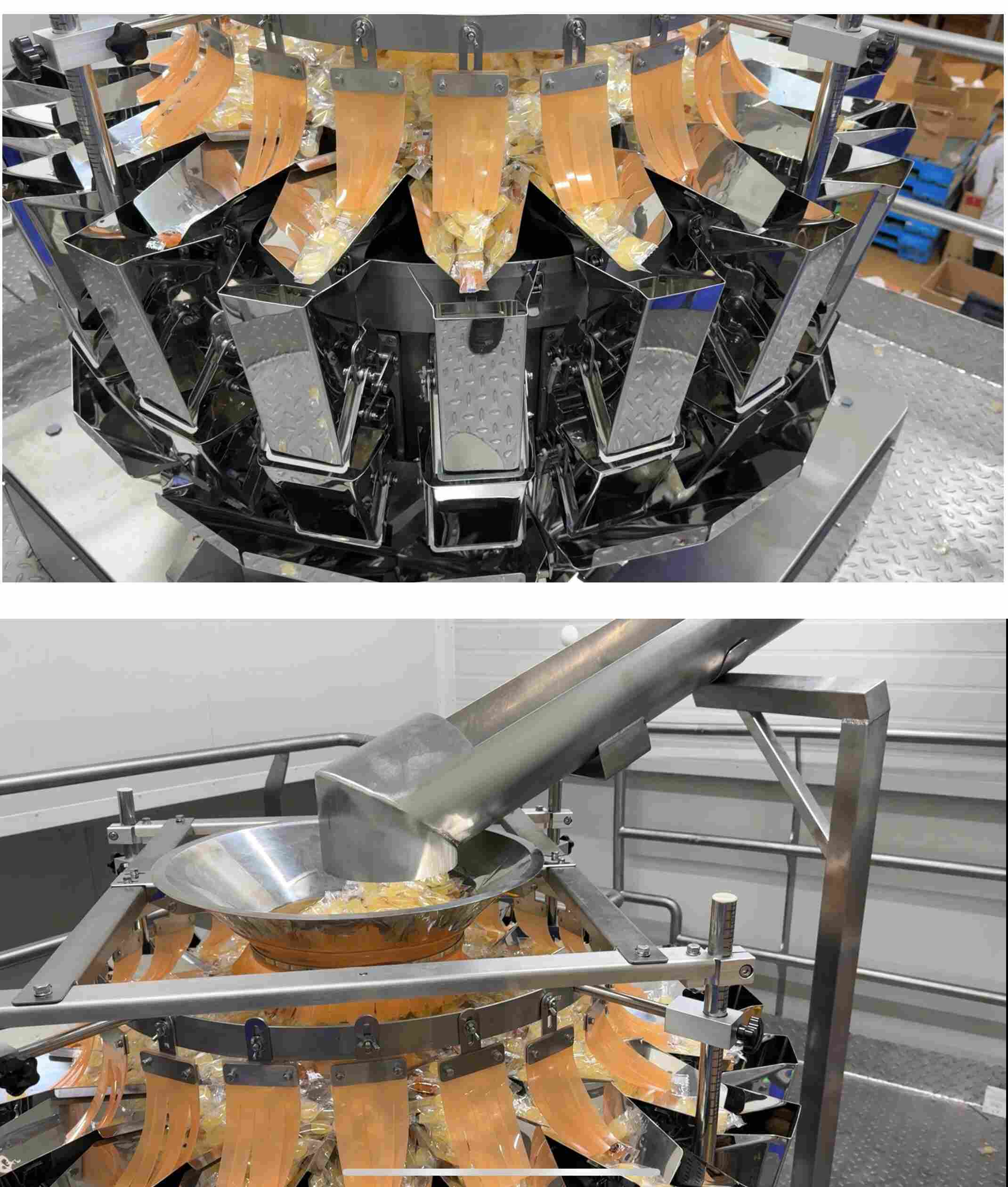

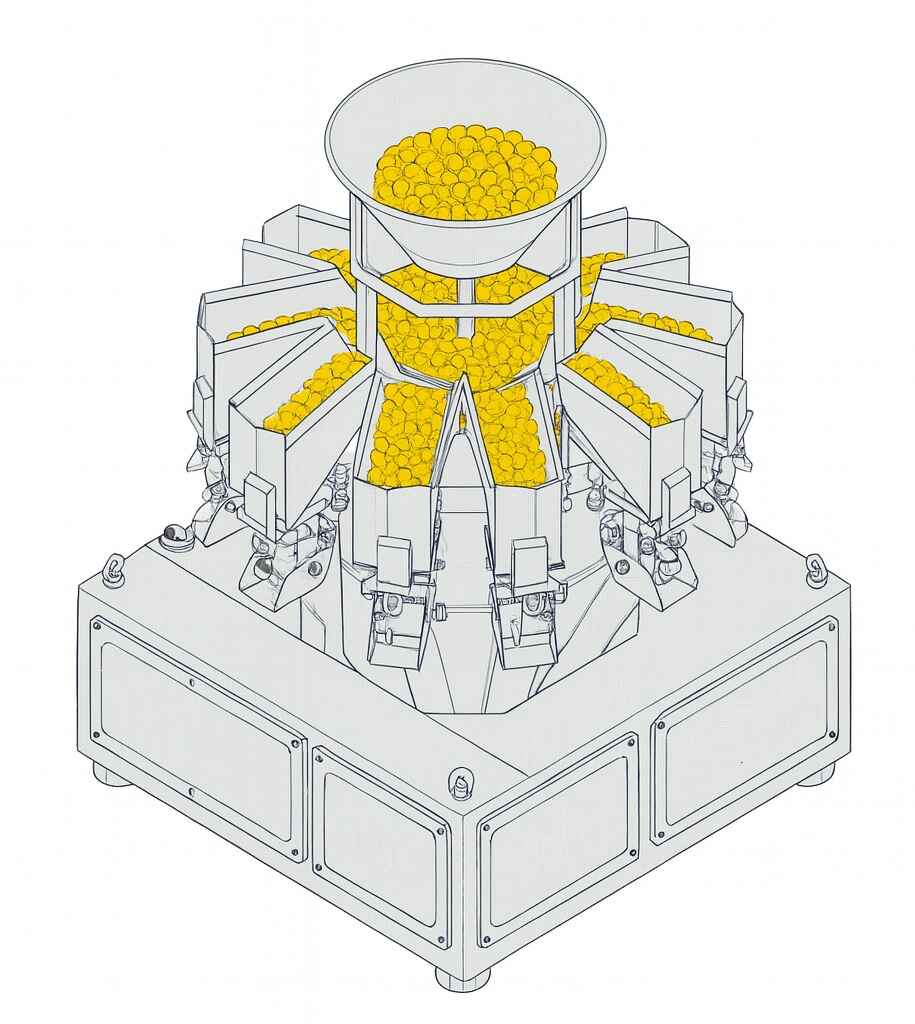

The Multihead Weigher by MEF is an advanced automatic weighing solution designed for high-speed, high-accuracy portioning of products. Ideal for snacks, dry fruits, confectionery, frozen foods, granules, and small hardware items, it delivers consistent weights with minimal giveaway. Equipped with multiple weighing heads, servo-driven feeders, and intelligent HMI controls, MEF’s multihead weigher ensures maximum efficiency in modern packaging lines. With its stainless-steel hygienic design, fast changeovers, and seamless integration with VFFS, HFFS, and pouch packing machines, this system is trusted across food, pharmaceutical, and FMCG industries to achieve precise, reliable, and cost-effective weighing.Why Choose MEF Multihead Weighers?

High-Speed Weighing Accuracy

The MEF multihead weigher is designed for fast, precise portioning, ensuring consistent weight distribution with minimal giveaway across snacks, dry fruits, frozen foods, and granules.

Advanced Multihead Technology

Equipped with 10, 14, or 20 weighing heads, the system uses intelligent combination algorithms to deliver optimal weighing accuracy and speed.

Compact & Hygienic Design

Built in stainless steel SS304/SS316, MEF multihead weighers comply with GMP standards and are easy to clean, making them suitable for food, pharma, and FMCG applications.

Flexible Product Handling

Handles a wide variety of granules, powders, small snacks, candies, and hardware items, offering unmatched versatility in weighing solutions.

Seamless Packaging Integration

Designed to integrate with VFFS, HFFS, pouch packing, and tray sealing machines for fully automated packaging lines.

Smart Control System

Featuring touchscreen HMI, recipe management, and self-diagnostics, the system ensures easy operation and reduced downtime.

Energy-Efficient & Low Maintenance

With servo-driven feeders and modular components, MEF multihead weighers provide long-term reliability and lower operational costs.

Preferred by snack, confectionery, frozen food, and nutraceutical manufacturers, MEF multihead weighers deliver faster ROI, reduced waste, and precision-driven weighing performance.

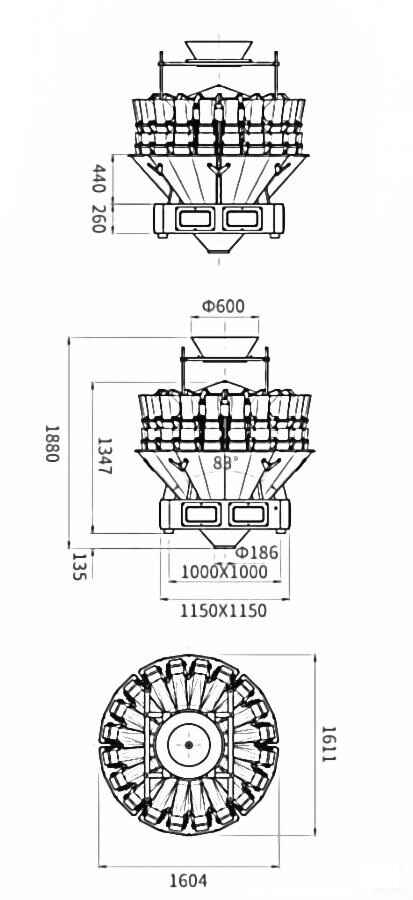

Technical Specifications

| Material of Construction (MOC) | Food-grade stainless steel SS304 with smooth finish; SS316 available for high-hygiene pharma & dairy applications. |

|---|---|

| Number of Heads | Available in 10, 14, 20, or custom configurations based on speed and accuracy requirements. |

| Weighing Speed | Up to 120 weighments/minute (product dependent). |

| Weighing Range | 10 g – 2000 g (adjustable depending on product type and head configuration). |

| Accuracy | ±0.1–1.5 g, minimizing giveaway and improving yield efficiency. |

| Control System | PLC/HMI touchscreen interface with recipe storage, diagnostics, and real-time performance monitoring. |

| Power Requirement | Approx. 2.5–4.0 kW depending on model and number of heads; 415 V, 3-phase, 50 Hz. |

| Air Requirement | Minimal compressed air (~0.5 bar) for pneumatic gates and discharge chutes. |

| Machine Weight | Approx. 500–900 kg depending on configuration. |

| Design Features | Compact modular design with IP65/IP66 washdown protection; detachable hoppers for quick cleaning. |

Optional Features

- Custom hopper designs for sticky, fragile, or free-flowing products

- Integrated dimple or Teflon-coated hoppers for non-stick operation

- Printer & labeler integration for batch/date coding

- Mix-weighing feature for combining two or more products in a single pack

- Metal detector or checkweigher integration for quality assurance

- Industry 4.0 enabled data logging and remote monitoring

Integration with Packaging Lines

The MEF Multihead Weigher integrates seamlessly with VFFS,HFFS, pouch packing, and tray sealing machines to deliver precise portions at high speeds. It is also compatible with conveyors and distribution systems for smooth product feeding and discharge.

Explore: Conveyors · VFFS Machines

Watch our multihead weigher machine on action

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of MEF Multihead Weighers

- High-accuracy combination weighing: Multiple heads calculate the best weight mix to minimize giveaway and maximize yield.

- Fast changeovers: Recipe-driven presets and tool-less hopper removal speed up product and pack size switches.

- Wide product versatility: Ideal for snacks, dry fruits, candies, frozen foods, pasta, grains, seeds, and small hardware items.

- Hygienic stainless design: Food-grade SS304/SS316, smooth surfaces, and easy washdown for GMP compliance.

- Smart HMI controls: Touchscreen interface with live stats, fault diagnostics, and production reporting.

- Seamless automation: Integrates with VFFS, HFFS, pouch packing, and tray sealing machines for high-speed packing lines.

Looking for full line automation? Pair our multihead weigher with cartoners and case packers for end-to-end packaging.

- Cost efficiency: Tight tolerances reduce product giveaway and improve margins.

- Consistent quality: Stable feed and precise discharge ensure uniform pack weights.

- Less downtime: Modular parts, self-diagnostics, and easy sanitation accelerate maintenance.

- Future-ready: Industry 4.0 connectivity for remote monitoring, data logging, and OEE analytics.

Applications

Designed for precise portioning where speed and accuracy directly impact product cost and quality.

- Snack foods (chips, namkeen, extruded snacks)

- Confectionery (candies, gummies, chocolates)

- Frozen foods (vegetables, nuggets, mixed items)

- Dry goods (pulses, rice, seeds, pasta, nuts)

Key Details

- Configurations: 10, 14, 20 heads (custom available)

- Speeds up to 120 weighments/min (product dependent)

- Typical range: 10 g – 2,000 g with ±0.1–1.5 g accuracy

- HMI with recipes, alarms, production counters, and reports

Industries & Applications

- Food & snacks: Chips, namkeen, trail mix, cereals

- Confectionery: Toffees, gummies, coated nuts

- Frozen & ready-to-eat: Veg mixes, finger foods

- Nutraceutical & FMCG: Granules, capsules (secondary), small components