Vertical Intermittent Motion Cartoner

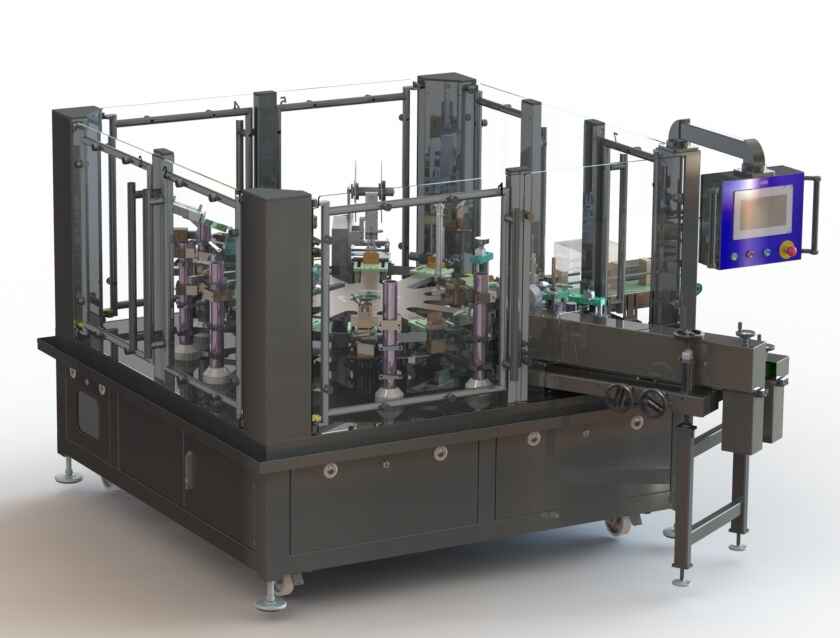

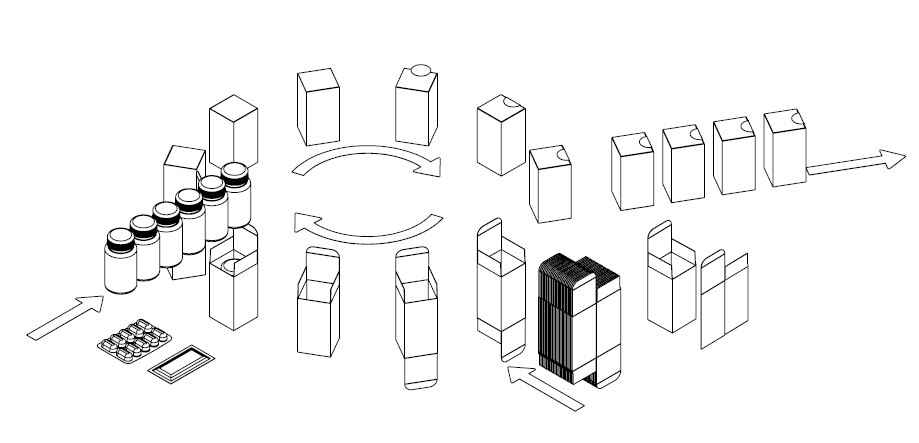

The Vertical Intermittent Motion Cartoner by MEF is a compact, versatile automatic cartoning machine engineered for high performance, simple operation, and low maintenance—available with a short lead time at a competitive price. Its mobile-blade carton pick-off and erection system pre-opens, erects, and transfers cartons reliably—even when using low-grammage board, square-section formats, or cartons with gluing/creasing imperfections.Why Choose This Vertical Cartoner ?

High Performance, Compact Footprint

Optimized for efficiency in limited spaces—ideal for pharmaceutical, food, cosmetics, and FMCG lines.

Reliable Carton Erection

The mobile blade inserts to pre-open cartons, then erects and places them between transfer lugs—stable with low-grammage cartons and imperfect creasing/gluing.

Vertical Product Introduction

Prevents orientation issues where horizontal loading could compromise final configuration or presentation (e.g., bottles, vials, blister packs, pouches).

Operator-Friendly & Hygienic

Cantilevered transfer and an extra-wide feeding area support multiple operators for manual feeding and enable easy cleaning.

Low Maintenance

Simplicity of use and access reduces downtime and total cost of ownership.

Designed for food, pharmaceutical, and cosmetics—built in SS304, with GMP hygiene and CE safety compliance. Vacuum-assisted pick & erection for low grammage cartons.

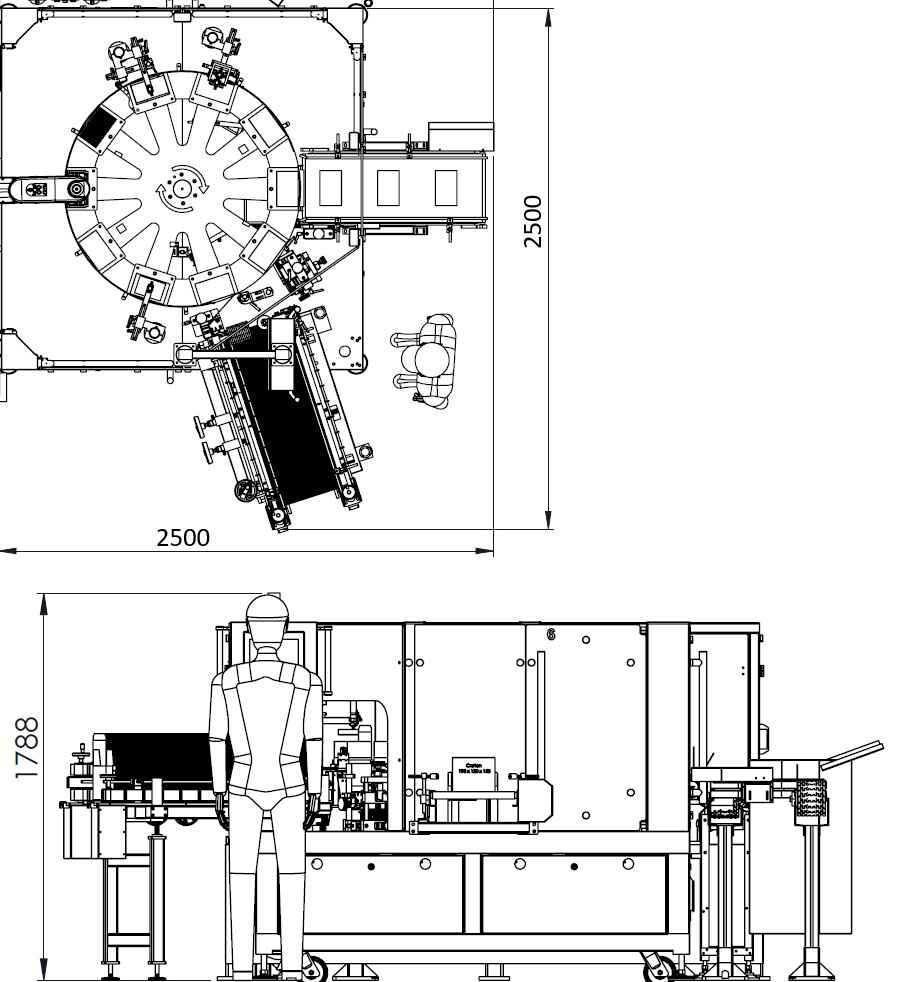

Technical Specifications

| Material of Construction (MOC) | SS304 (contact & frame). Optional SS316 for corrosive/sensitive products. |

|---|---|

| Speed | Up to 60 cartons/min (intermittent motion; depends on product/carton). |

| Drive & Control | Servo-driven (ABB/Siemens/Allen‑Bradley). PLC with HMI; recipe management and diagnostics. |

| Power Consumption | ~2.8 kW (energy‑efficient design; VFD where applicable). |

| Utilities | Compressed air 6 bar; SMC/Festo valves & actuators. |

| Carton Size Range (W × H × L) | 25 – 200 mm × 20 – 200 mm × 60 – 250 mm. |

| Changeover | Tool‑less adjustments, digital position indicators; quick changeover via recipes. |

| Safety | Transparent acrylic doors with CE-certified interlocks; e-stops and guards as per standards. |

| Machine Weight | Approx. 1,500 kg. |

| Construction | Cantilevered transfer for cleanability and operator access; centralized lubrication. |

Optional Add‑Ons

- Hot‑melt glue sealing system

- Inkjet / Laser coding (batch/date/serialization)

- Vision inspection (barcode/QR/label presence & print quality)

Line Integration

Seamless integration with upstream blister, flow‑wrap, and VFFS machines; downstream case packers and palletizers.

Explore: Case Packers · Palletizers

Watch our vertical cartoner machine on action

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of the Intermittent Motion Cartoner

- Mobile-blade pick-off & erection: Pre-opens, erects, and secures cartons into transfer lugs.

- Handles low-grammage board: Consistent even with square-section formats and minor gluing/creasing imperfections.

- Cantilevered carton transfer: Clean, unobstructed product introduction area—faster sanitation.

- Vertical loading: Protects product configuration and final presentation inside the carton.

- Wide feeding bay: Supports multiple operators for manual loading; smooth upgrade path to automatic feeding.

- Compact footprint & short lead time: Rapid deployment into existing packaging lines.

Looking for a horizontal cartoner?

- Built to last: Heavy-duty frame (~1,500 kg) for vibration-free operation.

- Compliance first: GMP-ready SS304 (SS316 optional) and CE-certified interlocked doors.

- Clean & easy: Cantilevered design with clear access and centralized lubrication.

- Industry 4.0 ready: PLC + HMI with diagnostics, data logging, and remote support.

Applications

Ideal for cartons where horizontal loading is impractical—ensures final configuration integrity.

- Pharma blisters, vials, bottles

- Food sachets, pouches, small cartons

- Cosmetics kits and personal care

Key details

- Recipe‑based quick changeovers (tool‑less)

- Accurate, repeatable servo motion

- Energy‑efficient (~2.8 kW)

- 6 bar pneumatic line (SMC/Festo)

Industries & Applications

- Pharmaceutical & nutraceutical: Blister packs, bottles, vials, sachets.

- Foods & confectionery: Pouches, bars, bags, flow-wrapped products.

- Cosmetics & personal care: Tubes, jars, small kits.

- Consumer goods & electronics: Small components and accessories.