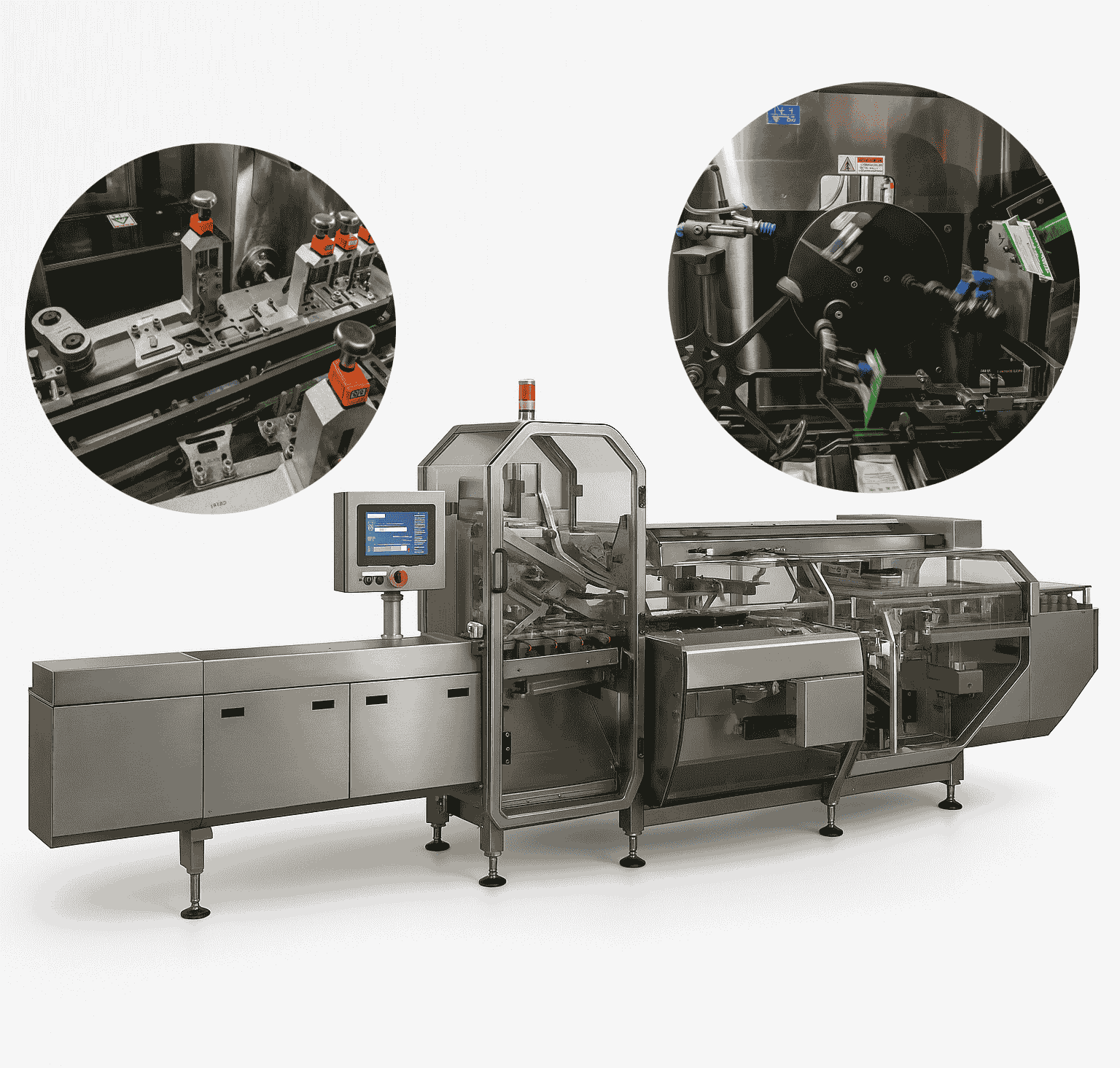

Horizontal Cartoner Machine

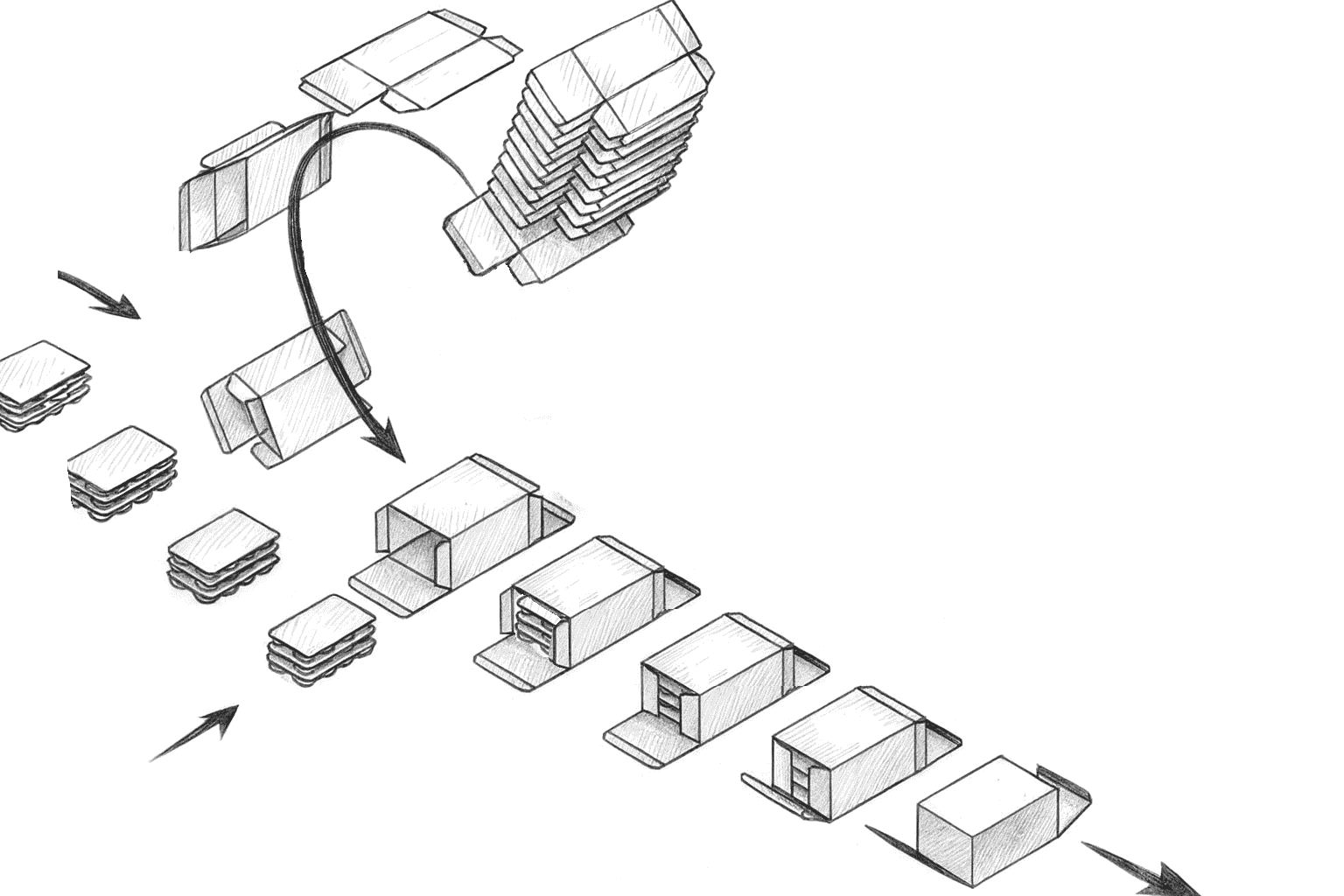

The Horizontal Cartoner Machine by MEF is a reliable, space-saving automatic cartoning solution designed for high speed, easy operation, and reduced maintenance—delivered with a short lead time and competitive cost. Its advanced carton pick-off, erection and transfer system ensures smooth handling, even with low-grammage cartons, irregular creases, or glue imperfections, making it ideal for consistent, high-quality packaging.Why Choose This Horizontal Cartoner?

High-Speed Continuous Packaging

Engineered for fast cartoning operations, the MEF Horizontal Cartoner ensures smooth carton erection, product insertion, and closing—ideal for high-volume food, pharmaceutical, and cosmetic lines.

Versatile Product Handling

Capable of packing a wide range of items including blisters, bottles, tubes, sachets, flow-wraps, and pouches, making it a universal solution for diverse product portfolios.

Compact Design, Maximum Output

With its space-saving layout and servo-driven control, the horizontal cartoner machine delivers excellent speed-to-footprint ratio, optimizing production floors without compromising performance.

User-Centric Operation

Equipped with an ergonomic loading station and intuitive HMI, operators can run and monitor the machine with ease, ensuring higher efficiency and reduced training time.

Sealing Options & Flexibility

Supports both tuck-in and hot-melt glue sealing, giving manufacturers the flexibility to adapt packaging to product and market requirements.

Integration Ready

Designed to work seamlessly with automatic feeders, conveyors, and robotic pick-and-place systems, ensuring smooth integration into complete packaging lines.

Durable & Low-Cost Ownership

Built in SS304/SS316 with GMP and CE compliance, the machine ensures hygiene, reliability, and long service life with minimal maintenance.

Trusted by pharma, food, and FMCG industries, MEF’s horizontal cartoner offers quick changeover, consistent performance, and future-ready automation compatibility.

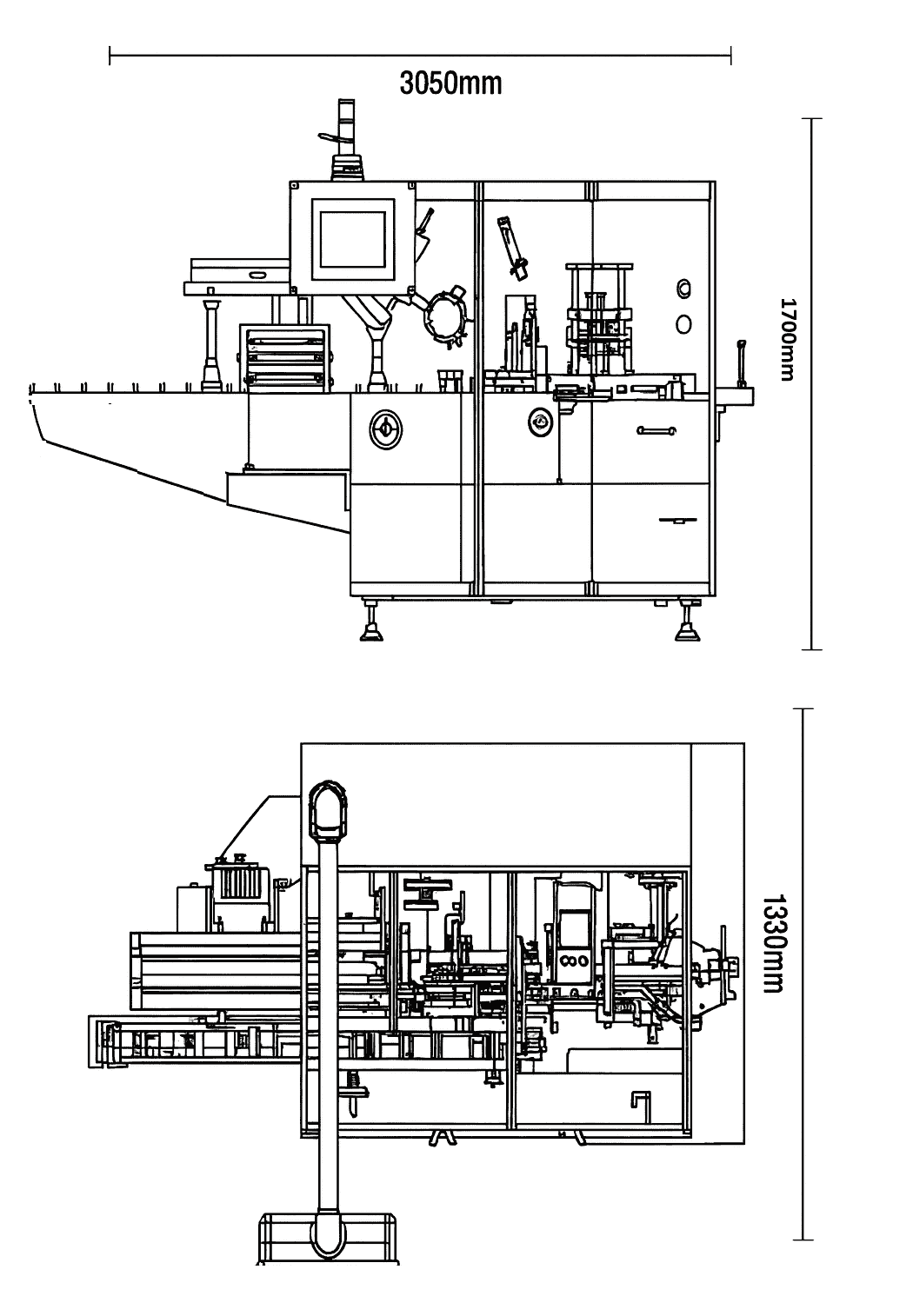

Technical Specifications

| Material of Construction (MOC) | Robust SS304 stainless steel for frame and contact parts; SS316 available for pharma and food-grade applications. |

|---|---|

| Operating Speed | Up to 300 cartons/min (continuous or intermittent motion depending on product type and carton size). |

| Drive & Control | Advanced servo-driven technology with Siemens/Allen-Bradley PLC and touchscreen HMI for recipe storage, alarms, and diagnostics. |

| Power Requirement | Approx. 4.5 kW, designed for energy-efficient operation with VFD-controlled drives. |

| Compressed Air | 6 bar, fitted with Festo/SMC pneumatics for smooth carton opening, flap folding, and sealing. |

| Carton Size Range (L × W × H) | 60 – 220 mm × 30 – 100 mm × 20 – 80 mm, adjustable for multiple carton formats. |

| Changeover | Fast changeover with minimal tools, handwheels with counters, and pre-set recipes for different SKUs. |

| Sealing Options | Mechanical tuck-in, hot-melt glue, or combination based on packaging requirements. |

| Machine Weight | Approx. 1,800 kg (varies by configuration and optional modules). |

| Design Features | Open-frame cantilever construction for hygiene, easy cleaning, and full operator accessibility. |

Optional Add-Ons

- Hot-melt glue sealing system with Nordson applicators

- Inkjet, laser, or thermal transfer coding for batch/date/serialization

- Vision inspection for leaflet presence, barcode/QR validation, and print quality

- Leaflet/brochure insertion units

- In-feed product collators and automatic feeders

Line Integration

The MEF Horizontal Cartoner is designed for seamless connection with upstream blister machines, flow-wrappers, and tube fillers, as well as downstream case packers and robotic palletizers.

Explore: Case Packers · Palletizers

Watch our Horizontal Cartoner machine on action

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of the Horizontal Cartoner

- Automatic carton erection & closing: Smooth opening, product insertion, and sealing with tuck-in or hot-melt glue.

- High-speed continuous motion: Capable of reaching up to 300 cartons/min depending on product type and format.

- Flexible product handling: Suitable for blisters, bottles, tubes, pouches, sachets, and flow-wrapped products.

- Compact design with high output: Saves floor space while maintaining maximum performance.

- User-friendly HMI & recipe storage: Quick changeover for multiple SKUs with digital position indicators.

- Seamless line integration: Works with feeders, conveyors, blister machines, and robotic pick-and-place systems.

Need a vertical cartoner? Explore our full cartoning range.

- Durable construction: Heavy-duty SS304 frame with optional SS316 for pharma & food industries.

- Compliance assured: GMP design, CE-certified interlocks, and operator safety systems.

- Efficient operation: Servo-driven carton transport ensures consistent accuracy and minimal downtime.

- Smart automation: PLC with HMI, alarms, data logging, and Industry 4.0 connectivity.

Applications

Designed for high-volume lines where horizontal product orientation delivers better efficiency and presentation.

- Pharmaceutical blisters, strip packs, bottles

- Food bars, chocolates, biscuits, and sachets

- Cosmetic tubes, creams, and jars

- Consumer goods, electronics, and daily-use items

Key Details

- Continuous or intermittent motion models

- Fast recipe-based changeovers with minimal tools

- Energy-efficient design (~4.5 kW)

- Pneumatics by SMC/Festo for reliable carton handling

Industries & Applications

- Pharmaceutical & nutraceutical: Blister packs, bottles, vials, strip packs, sachets

- Foods & confectionery: Biscuits, bars, cereals, chocolates, pouches

- Cosmetics & personal care: Tubes, creams, jars, small cartons

- Consumer goods & electronics: Accessories, components, multipacks