Automatic Case Packer Machine

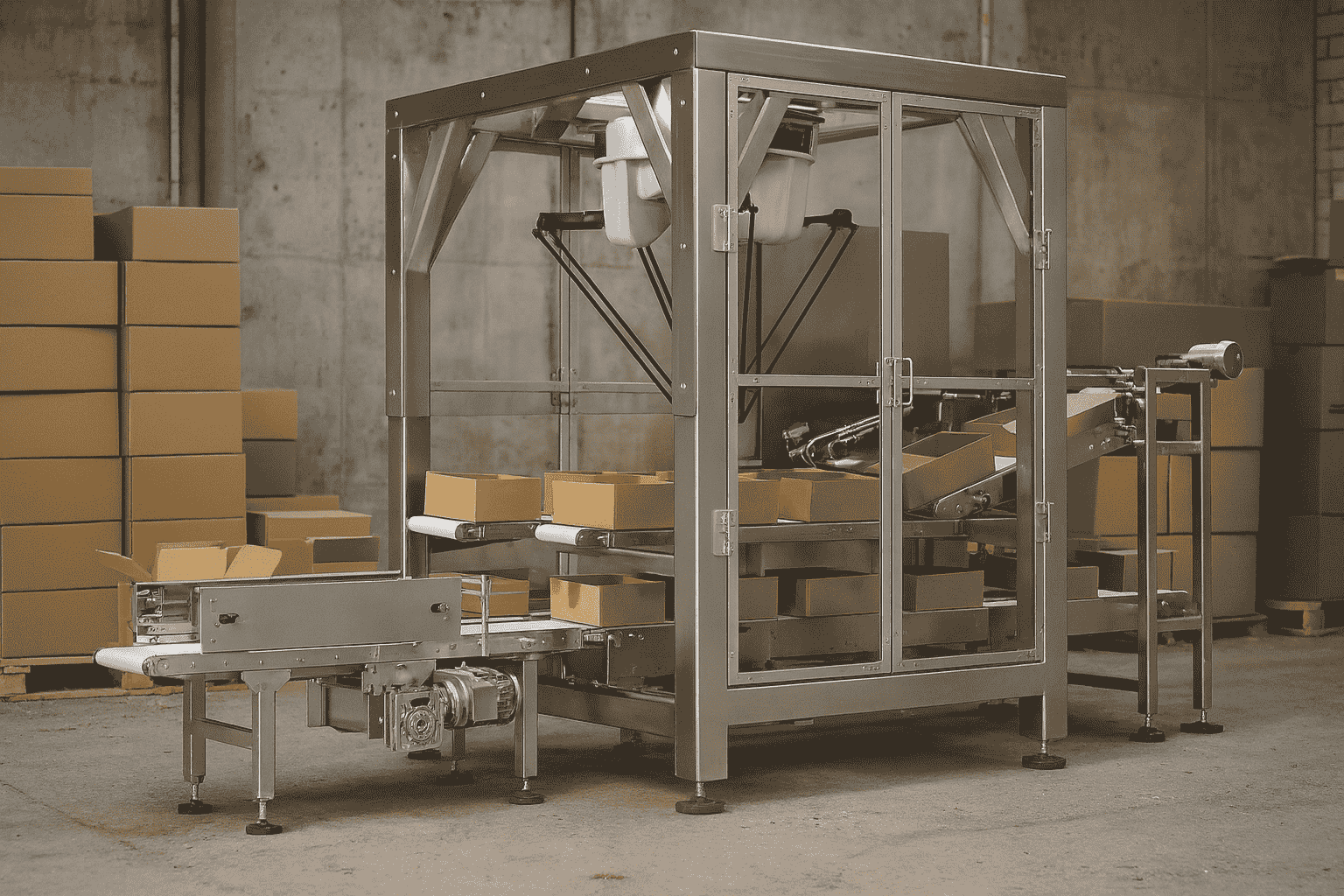

The Case Packer Machine by MEF is a versatile end-of-line packaging solution engineered for accuracy, durability, and flexibility. Available in top load, side load, front load, and bottom load configurations, it ensures secure case erection, smooth product loading, and reliable sealing for a wide range of pharmaceutical, food, cosmetic, and FMCG products. With its robust stainless-steel construction, servo-driven controls, and quick changeover capability, this machine delivers consistent performance, reduced downtime, and seamless integration into complete packaging lines.Why Choose MEF Case Packers?

Flexible Loading Styles

The MEF automatic case packer range is available in top load, side load, front load, and bottom load designs, giving manufacturers the flexibility to match their packaging process with product type and line layout.

Gentle Product Handling

Top and bottom load options are designed for fragile, heavy, or irregular products such as glass bottles, vials, and bulk food packs, ensuring product protection during packing.

High-Speed Side & Front Loading

For cartons, multipacks, and retail-ready products, side and front load case packers deliver reliable high-speed performance with neat, consistent loading every time.

Compact & Efficient Footprint

Optimized to save floor space while maintaining output, MEF case packers integrate smoothly into end-of-line packaging lines with minimal disruption.

Operator-Friendly & Accessible

Featuring intuitive HMI, ergonomic access points, and quick-change tooling, these machines reduce downtime and simplify training for operators.

Integration with Packaging Lines

Compatible with cartoners, blister machines, flow-wrappers, and palletizers, MEF case packers complete the automation cycle for secondary packaging.

Built for Reliability

Constructed from SS304/SS316 with GMP-compliant design and CE-certified safety interlocks, the system guarantees long service life, hygiene, and operator safety.

Trusted in pharmaceutical, food, cosmetic, and FMCG packaging lines, MEF case packers ensure consistent case quality, reduced manual labor, and cost-effective end-of-line automation.

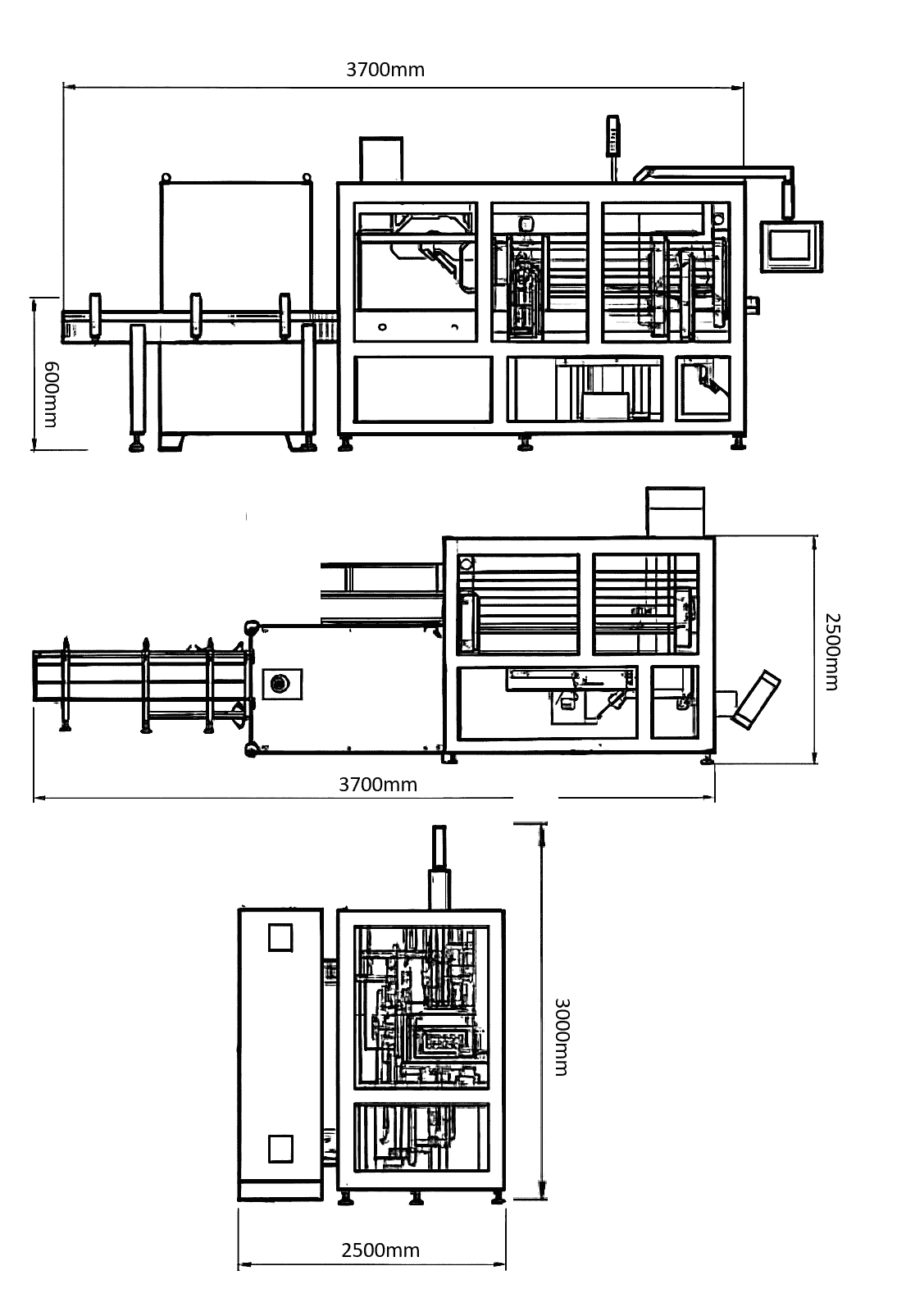

Technical Specifications

| Material of Construction (MOC) | Heavy-duty SS304 stainless steel for frame and guarding; optional SS316 contact parts for hygienic food and pharma applications. |

|---|---|

| Packing Speed | Up to 25 cases/min (varies with loading style – top load, side load, front load, or bottom load). |

| Drive & Control | Servo-controlled motion with Siemens/Allen-Bradley PLC, touchscreen HMI, recipe memory, and fault diagnostics. |

| Power Requirement | Approx. 5.0 kW with energy-efficient drives; optimized for 415 V, 3-phase, 50 Hz supply. |

| Compressed Air | 6 bar system using Festo/SMC pneumatics for smooth case erection, flap folding, and sealing. |

| Case Size Range (L × W × H) | 200 – 600 mm × 150 – 400 mm × 150 – 450 mm, adjustable for different product and shipping case formats. |

| Changeover | Quick changeover using recipe-based settings, tool-less adjustments, and digital position indicators for repeatability. |

| Closing/Sealing Options | Available with hot-melt glue, tape sealing, or tuck-in closures depending on load style and application. |

| Machine Weight | Approx. 2,000 kg (depends on load configuration and optional add-ons). |

| Design Features | End-of-line case packing with ergonomic operator access, modular layout for top/side/front/bottom load, and open design for easy cleaning and maintenance. |

Optional Features

- Automatic case erector and closer modules for higher throughput

- Hot-melt, tape sealing, or combination systems for secure closure

- Print & Apply labels for shipping, barcoding, and GS1 compliance

- Integrated checkweigher and reject station for quality assurance

- Collation systems for bottles, cartons, pouches, and multipacks

- Remote monitoring and Industry 4.0 connectivity options

Integration with Packaging Lines

The MEF Case Packer range—including top load, side load, front load, and bottom load models—is built to connect effortlessly with upstream equipment such as cartoners, flow-wrappers, and blister machines, while linking downstream to palletizers, stretch wrappers, and warehouse systems.

Explore: Cartoners · Palletizers

Robotic case packer

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of MEF Case Packers

- Multiple loading styles: Available in top load, side load, front load, and bottom load configurations to match product type and line layout.

- Gentle handling: Designed to protect fragile, heavy, or irregular items such as bottles, vials, jars, and glass containers.

- High-speed performance: Capable of packing up to 25 cases/min, depending on load style and product format.

- Compact & modular: Space-efficient footprint with modular design for easy expansion and upgrades.

- Smart HMI control: Touchscreen interface with recipe storage, quick changeovers, and fault diagnostics.

- Line-ready integration: Connects with cartoners, flow-wrappers, blister lines, and palletizers for seamless automation.

Need an automatic cartoner? See how our solutions connect across the entire line.

- Durability: Built with SS304/SS316 and heavy-duty frame for long-term operation.

- Compliance: CE-certified interlocks, GMP design, and operator safety systems.

- Efficiency: Servo-driven motion ensures accurate, repeatable case packing with minimal downtime.

- Future-ready: Industry 4.0 connectivity, data logging, and remote support features included.

Applications

Ideal for secondary packaging and end-of-line automation where secure case packing is critical.

- Pharma blisters, bottles, vials, cartons

- Food bars, biscuits, cereals, pouches

- Cosmetic tubes, jars, multipacks

- Consumer goods, electronics, and accessories

Key Details

- Speeds up to 25 cases/min depending on configuration

- Quick changeover with recipe-driven settings

- Energy-efficient design (~5.0 kW)

- Pneumatics powered by Festo/SMC for smooth case handling

Industries & Applications

- Pharmaceutical & nutraceutical: Bottles, vials, blisters, cartons

- Food & beverages: Biscuits, chocolates, snack bars, cereals, flow-wraps

- Cosmetics & personal care: Tubes, creams, jars, multipacks

- Consumer goods & electronics: Household items, devices, components