About Us

Our Journey:MEF Story

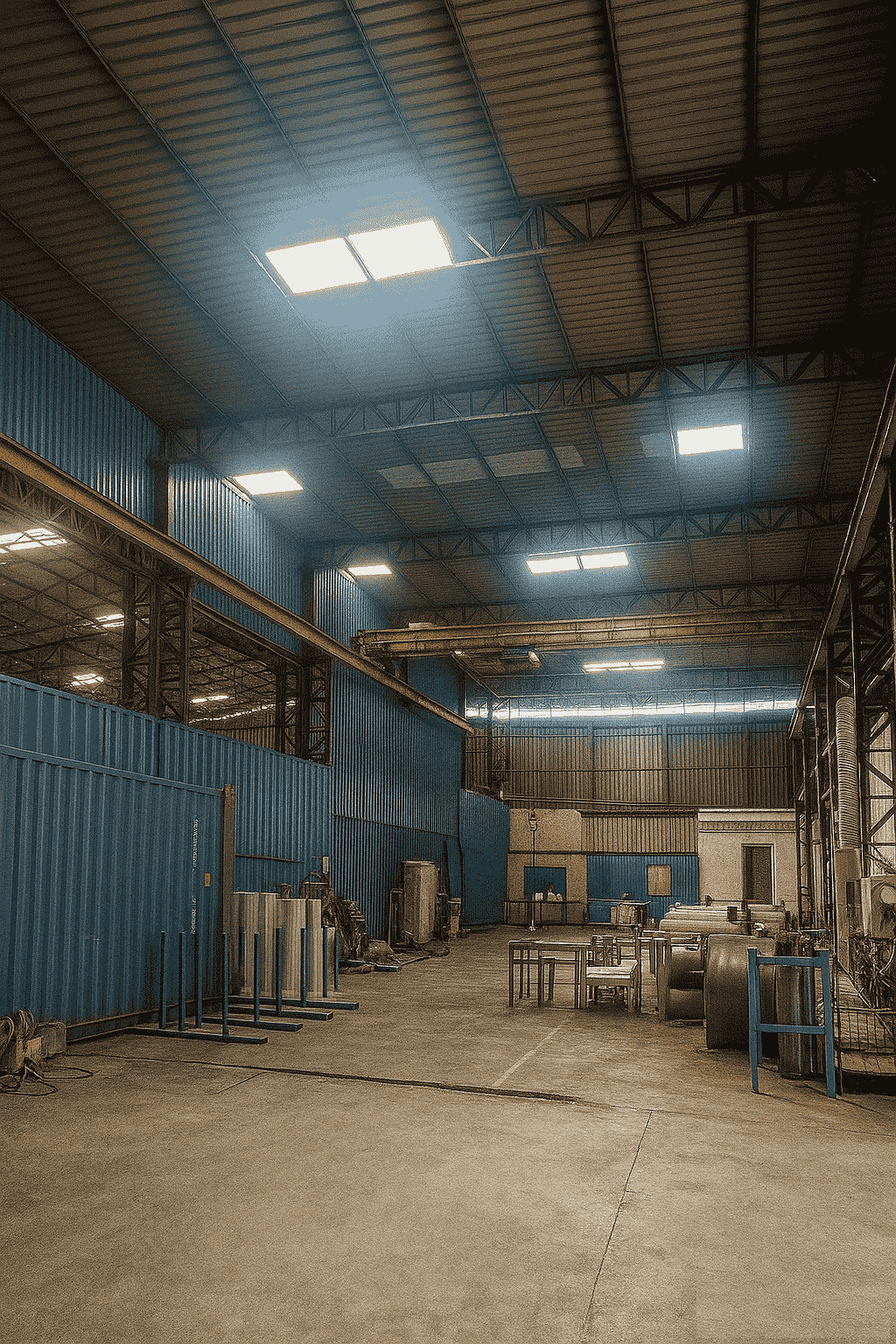

Discover the history and evolution of MEF [maharashtra engineering and fabrication]. Our timeline showcases the key milestones, innovations, and moments of growth that have shaped our journey. From our humble beginnings in 2010 to becoming a recognized name in the food and pharma sector, explore the story that defines our commitment to Customer Success.

-

2010

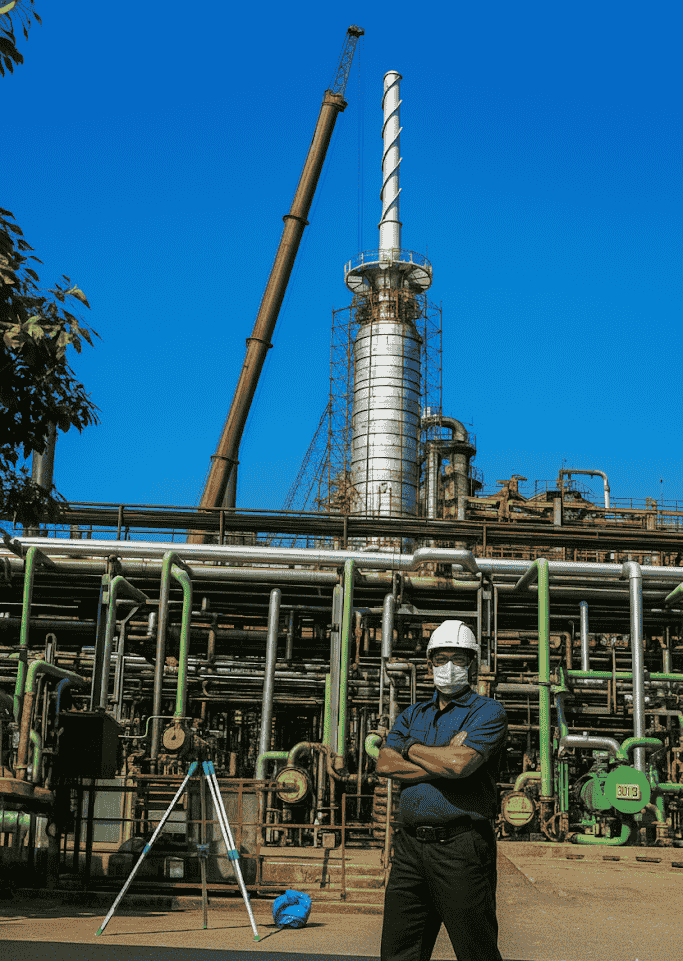

Our journey began in Bhosari, Pune, India, with a clear mission – to deliver uncompromising quality in precision machining and engineering solutions. Over the years, we have earned the trust of industry leaders by consistently providing high-accuracy, reliable, and timely machining services. One of our proudest milestones has been supporting Alfa Laval’s food and beverage division with critical machining work, ensuring their global standards are met with excellence.

-

2011

2011: Investing in Quality & Capability. Building on our early success, we made significant investments in our future. We enhanced our production capabilities with a new, high-precision servo lathe machine and formally began the rigorous journey toward ISO 9001 certification.

-

2012

2012: Specializing in Precision Engineering. We leveraged our growing expertise to specialize in manufacturing high-precision machined parts for the demanding food and beverage engineering sector. This strategic focus established our Pune facility as a key supplier of custom components where accuracy, hygiene, and food-grade quality are paramount. Our services became critical for companies seeking reliable engineering solutions that met the industry's most stringent specifications.

-

2013

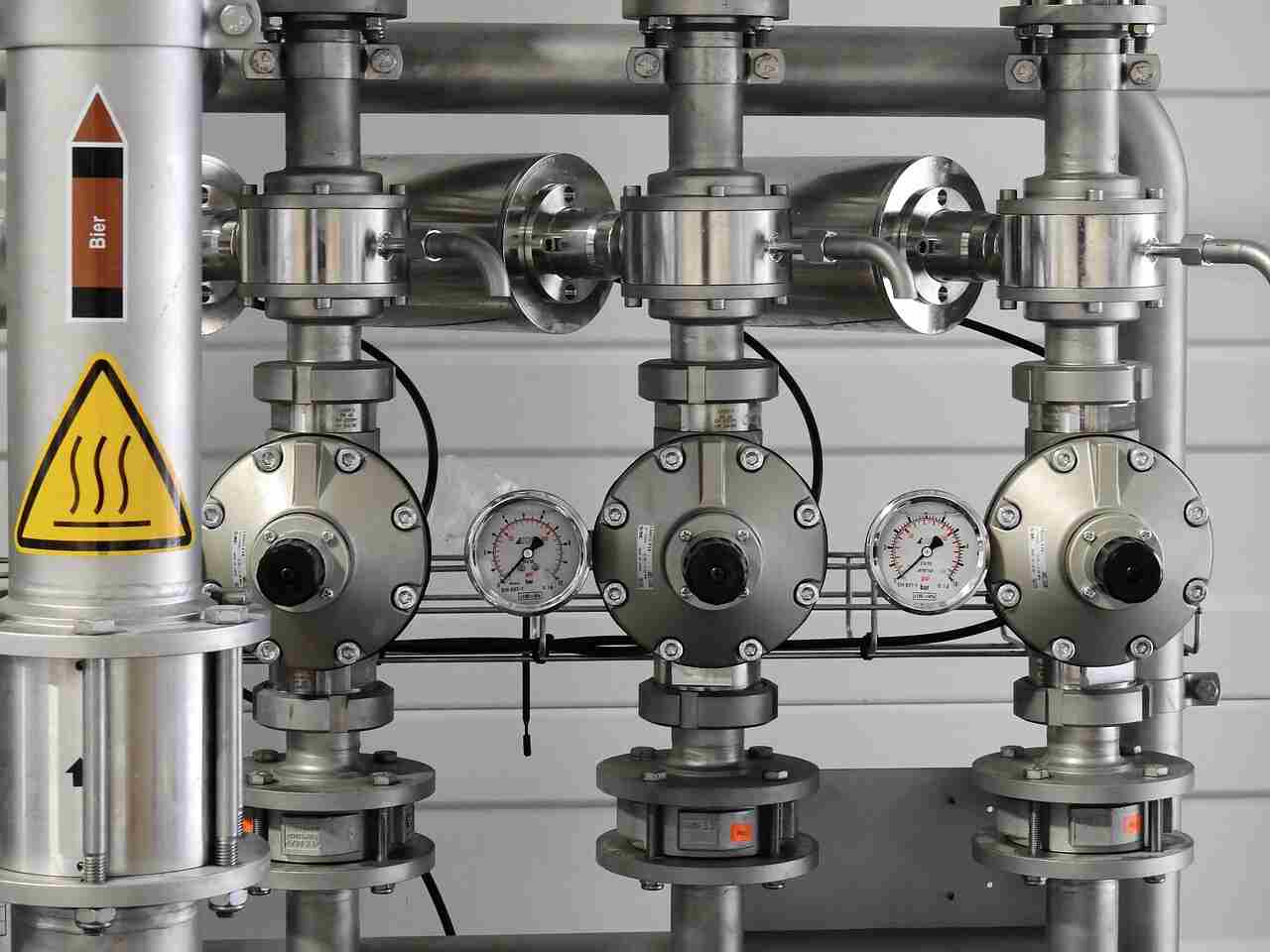

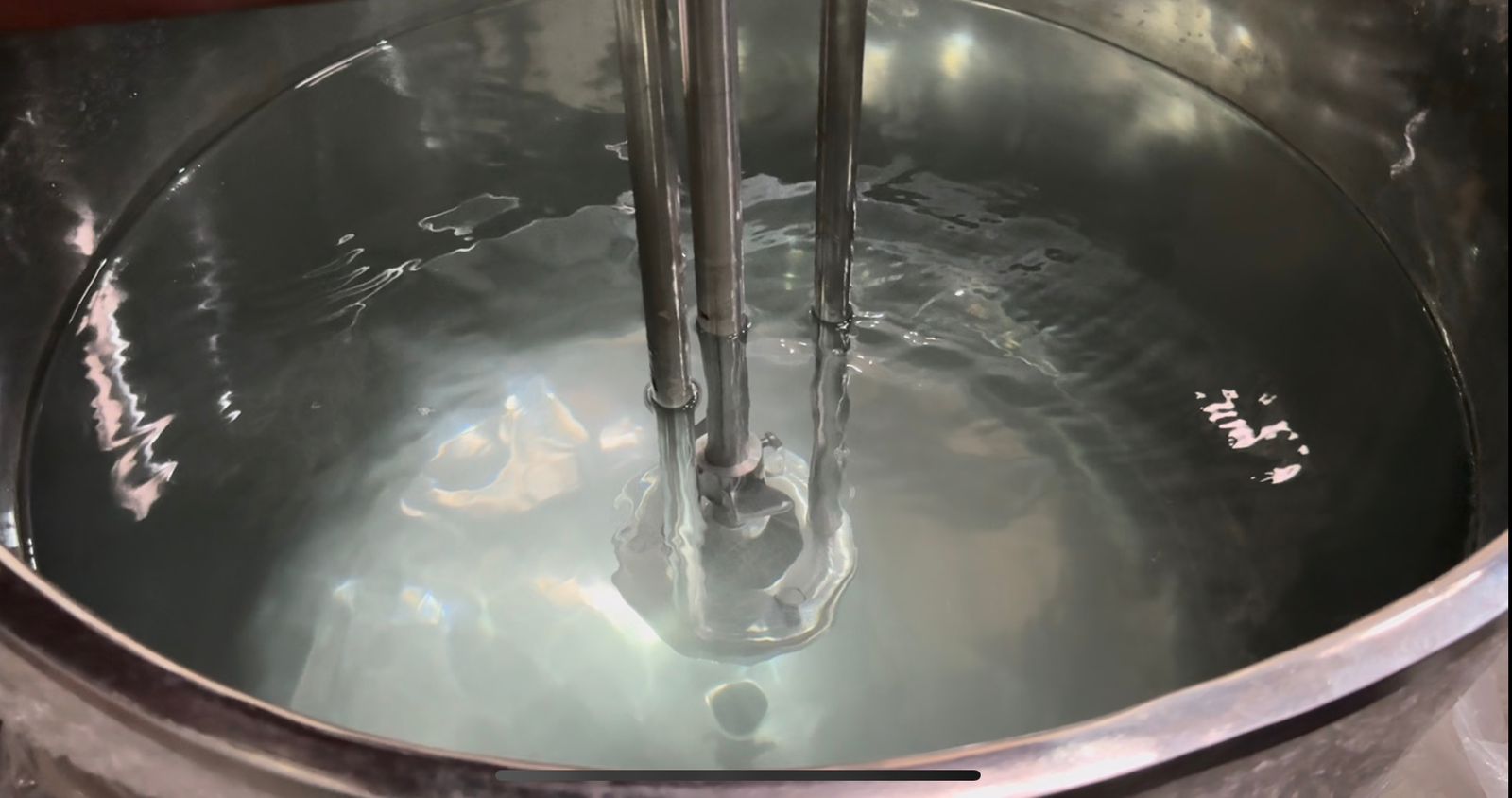

2013: Delivering Complete Fabrication Solutions. This was a landmark year. We mastered the fabrication of both high-grade milk processing tanks and complex pressurized stainless steel piping systems. This required advanced expertise in SS316 fabrication, sanitary polishing, and specialized TIG welding, allowing us to deliver complete, integrated process solutions for the food and dairy industries.

-

2014

2014: Advancing into Process Automation. We elevated our expertise from fabrication to full system integration. We delivered a complete food processing line featuring pressurized piping integrated with precision liquid flow control valves. By implementing sophisticated PLC and PID control systems, we provided our client with automated, highly accurate process control. This marked our evolution into a provider of intelligent industrial automation solutions in Pune.

-

2015

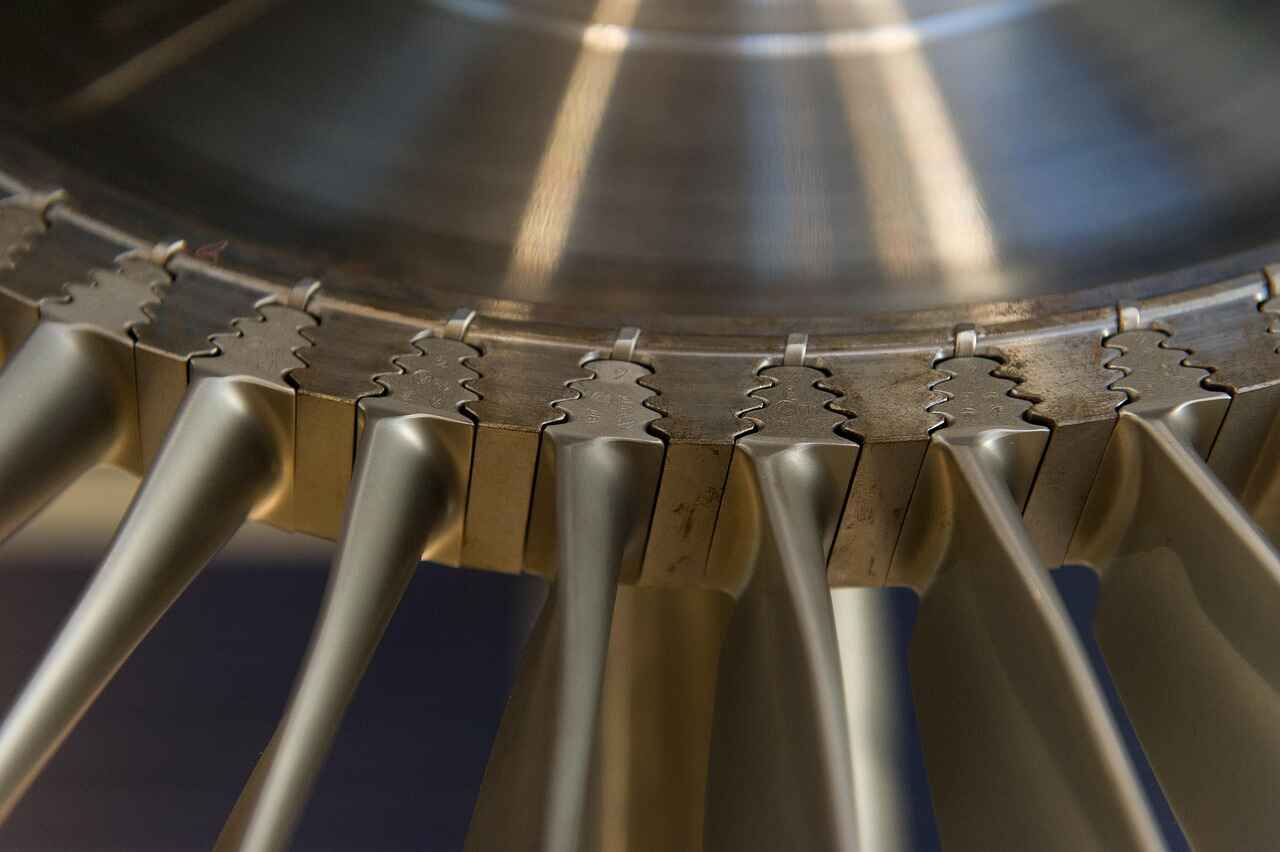

2015: Developing In-House Design & Engineering Excellence. We transitioned from manufacturing to original product design by developing our own proprietary agitator for high-viscosity sugar syrup. This project showcased our advanced engineering, featuring a 3-meter hollow shaft operating at 300 RPM with a remarkable total runout of just 0.5mm. This level of high-precision machining solidified our reputation as a provider of specialized, high-performance solutions for the food processing industry.

-

2016

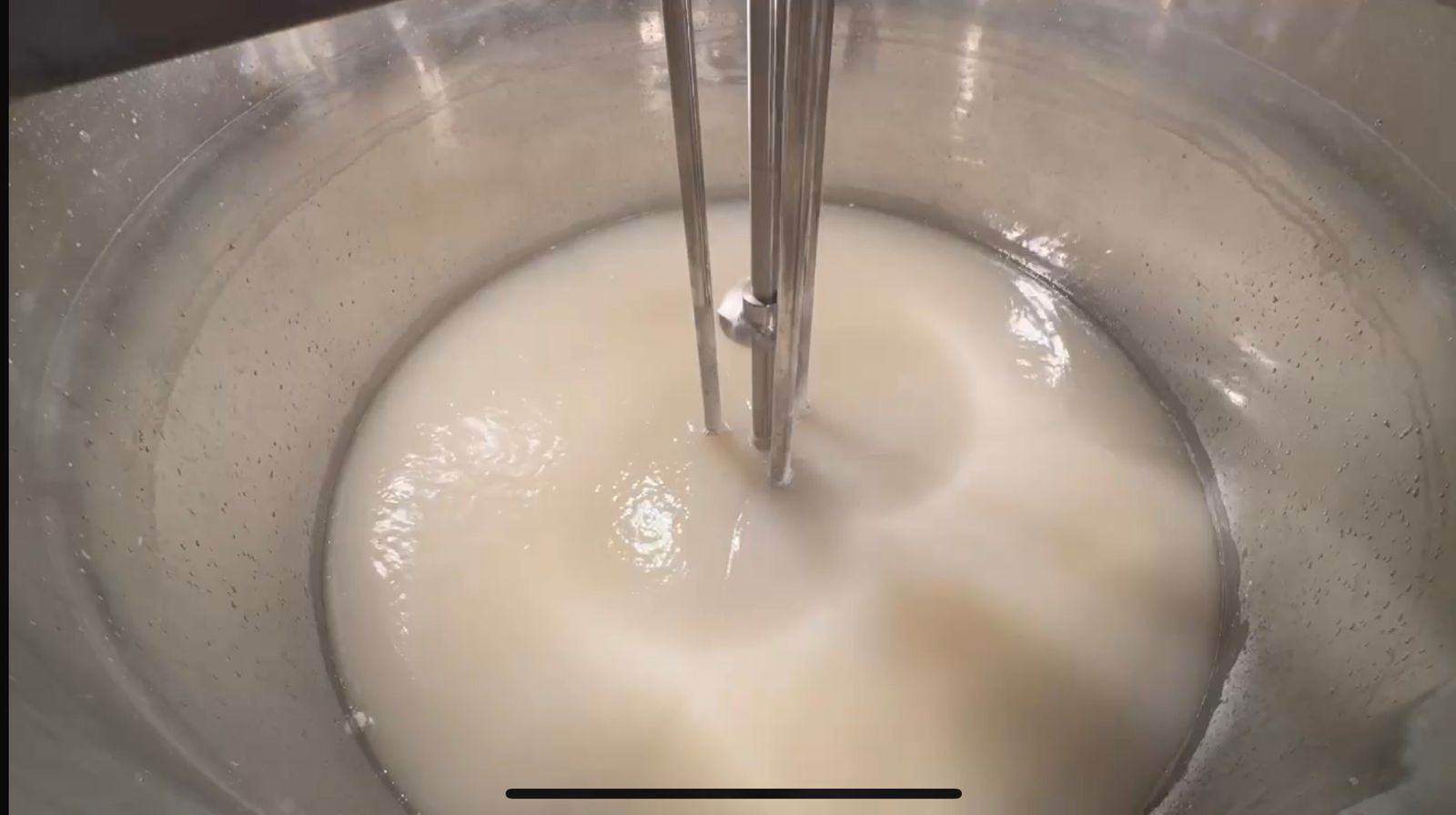

2016: Engineering a Breakthrough in High-Viscosity Mixing. This year, we solved a significant process engineering challenge by developing a custom high-shear mixer for xanthan gum solutions. The goal was to successfully blend a highly viscous mixture of 10% xanthan gum and 300kg of sugar into just 150 litres of water within a 500-litre tank. After extensive R&D, multiple prototypes, and rigorous testing, our team engineered a successful 1400 RPM mixer design. This achievement proved our advanced capabilities in custom equipment design and our ability to engineer solutions for the most demanding high-viscosity applications in the food and beverage industry.

-

2017

Engineering Advanced Automation with Machine Vision. We engineered a sophisticated smart conveyor system for the logistics industry. The system synchronized a high-resolution camera for object identification, a precision encoder for positional tracking, and a Variable Frequency Drive (VFD) for dynamic motor speed control. This integration allowed for precise, real-time sorting and handling of packages, marking a significant achievement in our ability to deliver complex, fully integrated automation solutions.

-

2018

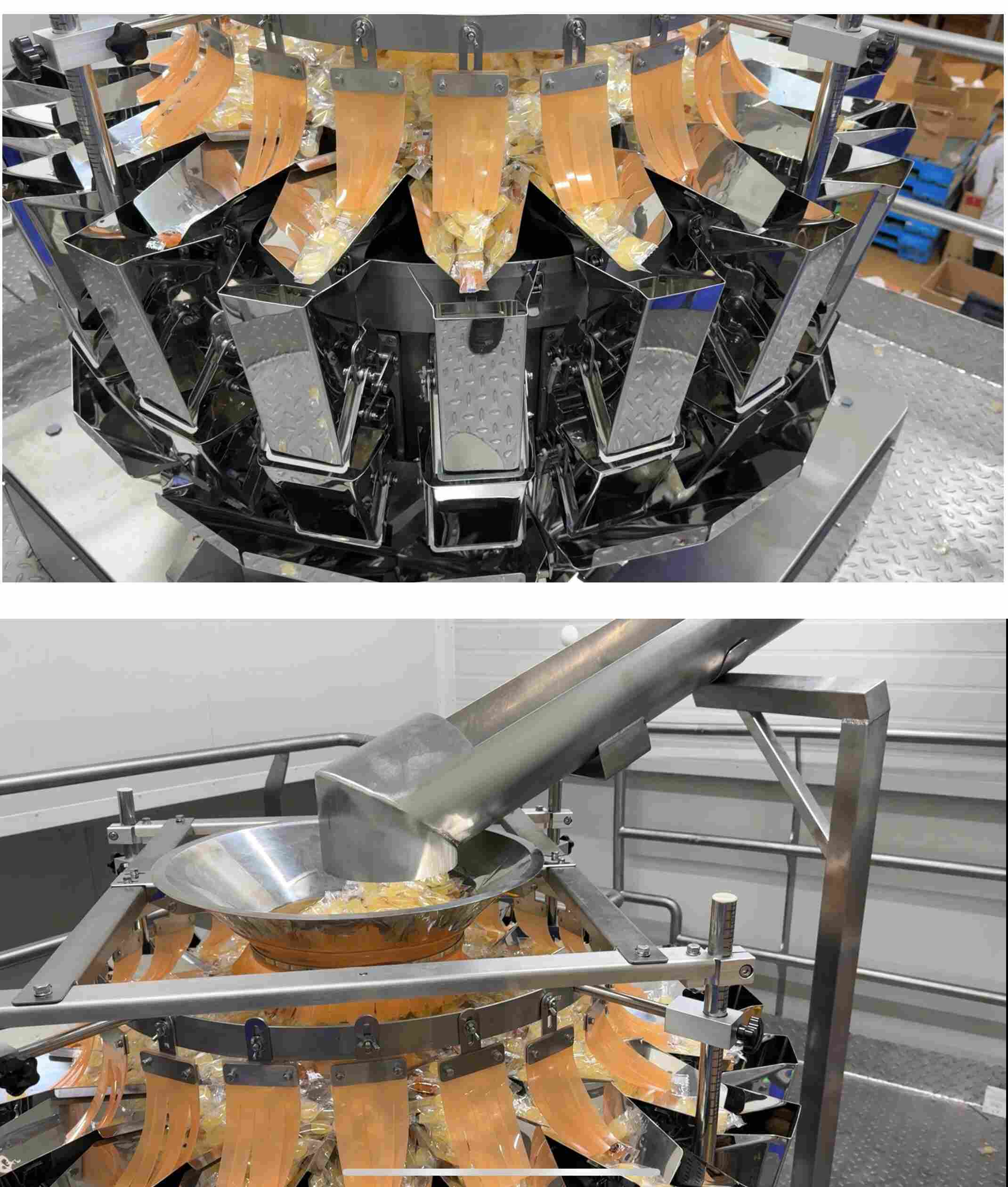

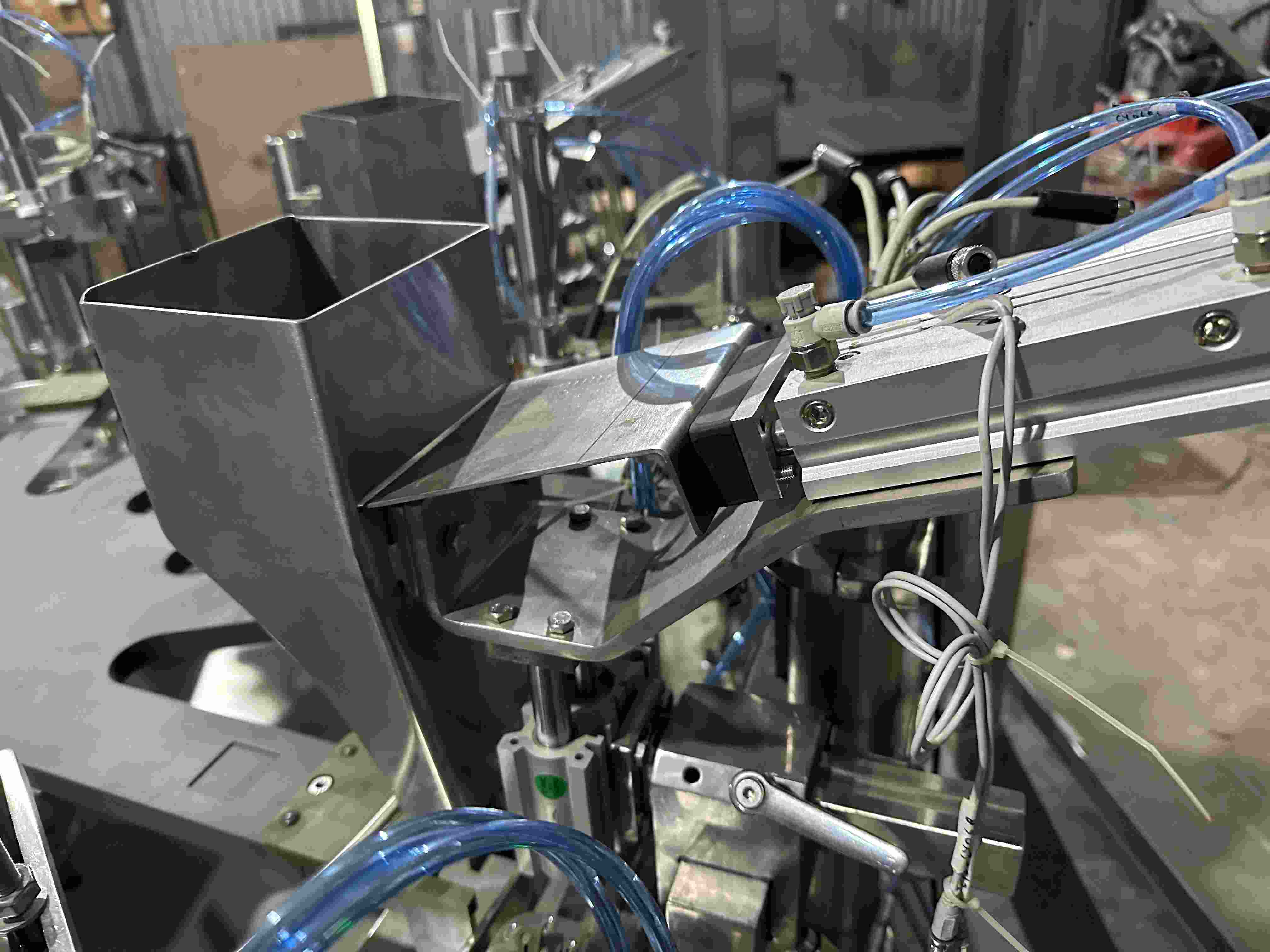

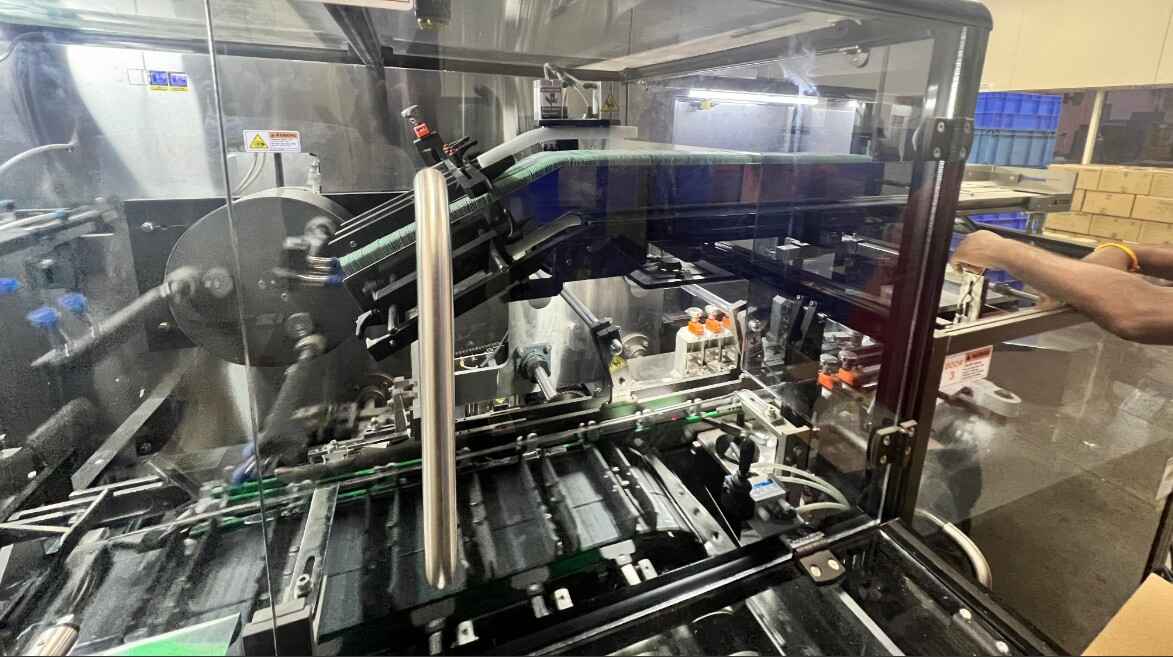

We Commissioned Advanced Weighing & Packaging Solutions. We entered the automated packaging market by commissioning our MEF Multihead Weigher on client production lines. This advanced weighing solution, engineered for high-speed and high-accuracy portioning, showcased our expertise in servo-driven systems and intelligent HMI controls. With its hygienic, stainless-steel design, our weigher provided critical efficiency for the food, pharmaceutical, and FMCG industries, establishing us as a key provider of integrated packaging line technology.

-

2019

Expanding Our Packaging Line with Advanced Cartoning. We continued to innovate in the packaging sector by commissioning our MEF Vertical Intermittent Motion Cartoner. Engineered for high performance, this machine featured a unique carton erection system capable of reliably handling challenging materials like low-grammage board at speeds of 60 cartons per minute. This versatile automatic cartoning solution solidified our position as an end-to-end provider for modern packaging lines.

-

2020

2020: Completing Our Cartoning Portfolio with a Horizontal Solution. We expanded our packaging automation offerings by developing the MEF Horizontal Cartoner Machine. This high-speed, space-saving solution was engineered for reliability, featuring an advanced system to handle challenging materials like low-grammage cartons. By adding a versatile horizontal automatic cartoning solution to our portfolio, we could now offer a comprehensive range of end-of-line packaging equipment.

-

2021

2021: Providing Complete End-of-Line Packaging Solutions. We solidified our position as a full-line packaging provider by introducing the MEF Case Packer Machine. Engineered for flexibility with multiple configurations (top, side, front, and bottom load), this machine offered a robust automatic case packing solution for the food, pharmaceutical, and FMCG industries. By delivering a reliable, servo-driven system, we enabled clients to automate their entire packaging process, from initial weighing to final case sealing.

-

2022

Delivering Global Turnkey Solutions with Containerized Plants. We marked a major milestone by delivering our first project to an overseas client. We engineered, built, and commissioned a complete, portable process plant housed within a 40ft container. This fully automated, turnkey solution included all necessary tanks, integrated process lines, and control systems, demonstrating our capability to deliver complex, skid-mounted systems for rapid international deployment.

-

2023

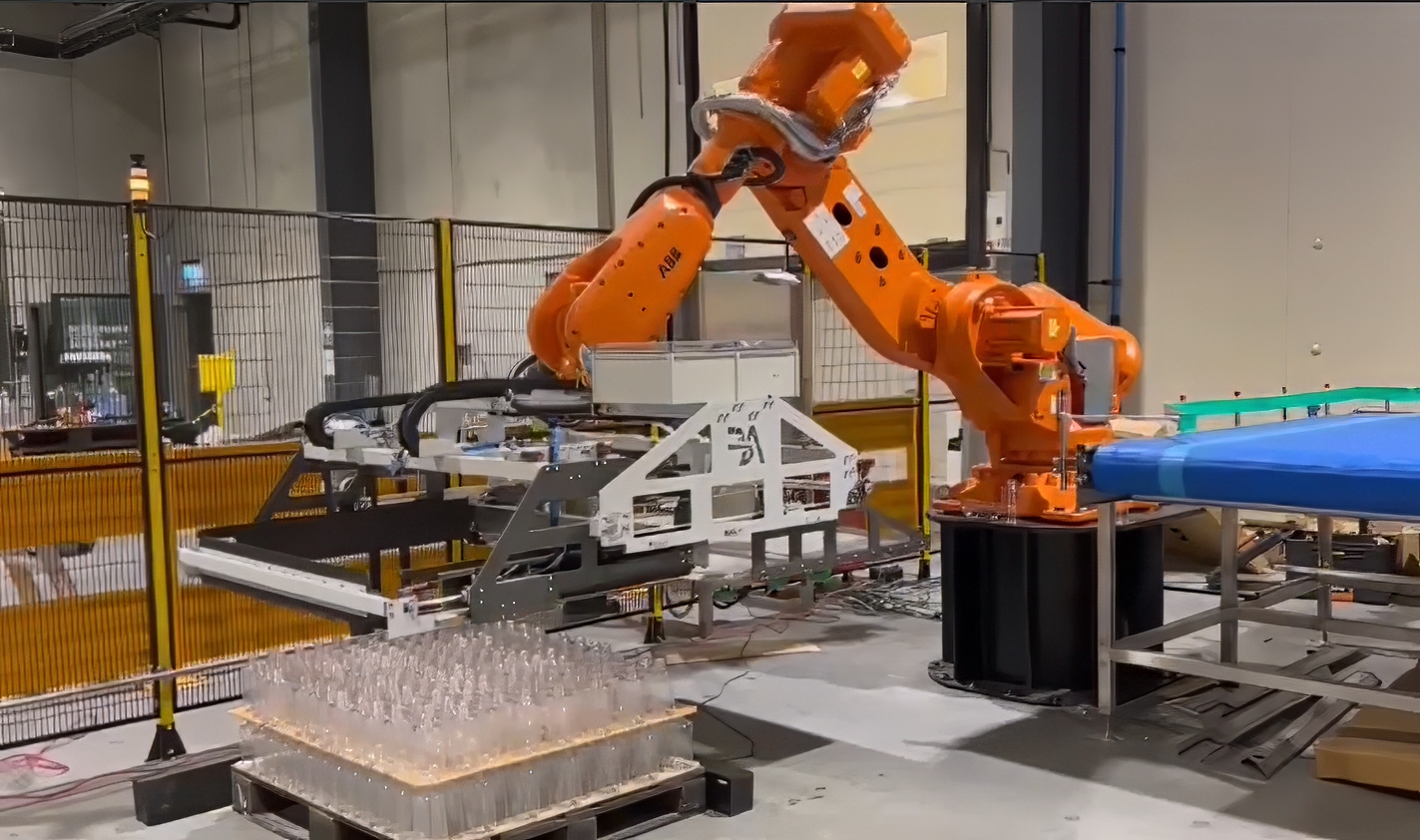

2023: Embracing Industry 4.0 with Robotic Palletizing. We stepped into the future of smart manufacturing by developing the MEF Robotic Palletizer. This advanced end-of-line automation system utilized a high-speed robotic arm to handle everything from cartons to bags and trays. Engineered to be Industry 4.0 compatible, our solution offered clients greater efficiency and safety, solidifying our role as a provider of next-generation automation.

-

2024

2024: Completing the Loop with Robotic De-Palletizing. We expanded our Industry 4.0 offerings by developing the MEF Robotic De-Palletizer. As a counterpart to our palletizing system, this solution created a complete, end-to-end robotic handling loop for our clients. Engineered for precision and safety, it automates the unloading of pallets, seamlessly feeding products into packaging lines and solidifying our expertise in creating fully integrated, smart factory solutions.

More about MEF (Maharashtra Engineering and Fabrication)

The company was established on 4th March 2010 by Mr. Sikandar Tarasgar, a seasoned Mechanical Technician with over 20 years of experience in the Gulf region, including a distinguished tenure at Alfa Laval, a globally recognized leader in heat transfer, separation, and fluid handling technologies.

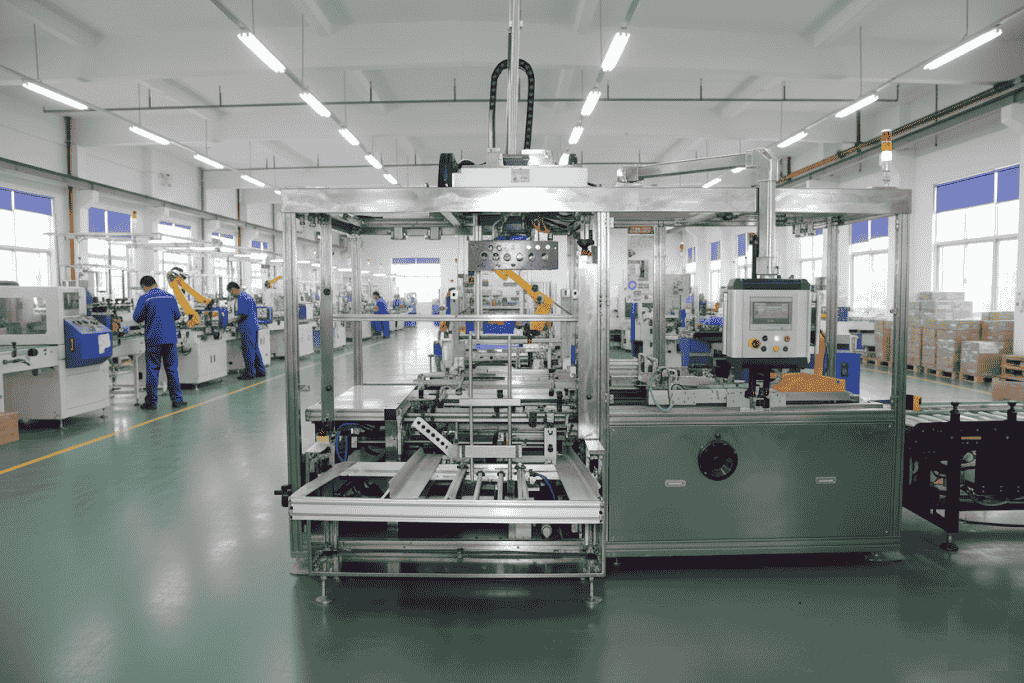

Under his visionary leadership, Maharashtra Engineering and Fabrication (MEF) has transformed from a fabrication-focused company into a cutting-edge engineering firm, specializing in industrial automation, including case packers, robotic packaging lines, and customized automation solutions.

In 2010, Mr. Tarasgar founded MEF with the vision of bringing international standards of engineering and fabrication to India. Today, MEF is known for consistently delivering high-quality solutions and building enduring relationships with its customers.

MEF is a premier provider of automated packaging solutions, serving the Food, Beverage, Home & Personal Care, Pharmaceutical, and Chemical industries. Backed by a dedicated team of over 50 professionals, we offer end-to-end solutions encompassing filling systems, end-of-line automation, and complete line engineering.

Our commitment to innovation places us at the forefront of packaging automation. By integrating advanced robotics and adhering to Industry 4.0 principles, we help clients build smart factories that offer greater efficiency, precision, and adaptability.

MEF’s solutions are engineered to meet the highest standards of quality and safety, especially critical in sectors like food and pharmaceuticals. Our technology-driven approach empowers clients to achieve operational excellence and stay ahead in competitive markets.

In 2022, MEF entered a strategic joint venture with Beyond Automation, based in New Zealand. Through this collaboration, we have adopted state-of-the-art design and automation technologies that enhance our capabilities and global competitiveness.

As a result of this partnership, MEF now serves a growing international clientele, with a strong presence in Australia and Turkey. Our global experience allows us to deliver world-class automation solutions tailored to regional needs.